Warped Steel

What can be done with steel that has been warped? How could it have been prevented in the first place?

Warpage and distortion of hot-dip galvanized steel can be prevented with proper design procedures. However, there are still times when a design flaw will lead to warped steel after the galvanizing process. If warped steel parts do result, they may be recoverable. For example, the fabrication below is not severely out of a plane and is made of relatively thinner steel. It may be possible to bend this steel back into its correct shape or clamp and bolt it into place as is.

Thicker pieces that are severely out of a plane like the steel shown below may not be recoverable. It may be extremely difficult to bend the steel back into place and may also damage the coating.

As always, the most effective way to deal with warpage and distortion of hot-dip galvanized parts is to reduce risks during the design stages. The following steps should be taken during the design stage to minimize the chance of warpage and distortion.

- Where possible, use symmetrically rolled sections in preference to angle or channel frames. I-beams are preferred to angles or channels.

- Use parts in an assembly of equal or near equal thickness, especially at joints.

- Use temporary bracing or reinforcing on thin-walled and asymmetrical designs.

- Bend members to the largest acceptable radii to minimize local stress concentration.

- Accurately pre-form members of an assembly so it is not necessary to force, spring, or bend them into position during joining. Continuously weld joints using balanced welding techniques to reduce uneven thermal stresses. Pinholes from welding are very dangerous in items to be galvanized and must be avoided. Staggered welding techniques to produce a structural weld are acceptable. For staggered welding of 1/8-inch (4 mm) or lighter material, weld centers should be closer than 4 inches (10 cm).

- Avoid designs that require progressive dip galvanizing. It is preferable to build assemblies and subassemblies in suitable modules so they can be immersed quickly and galvanized in a single dip. In this way, the entire fabrication can expand and contract uniformly. Where progressive dipping is required, consult your galvanizer.

Theres also an option to make an asymmetrical piece into a symmetrical shape. The unrecoverable beam we saw before, for example, could have been made more symmetrical by welding a similar U-shaped piece to the bottom as well as the top. This could cause the internal stresses in the bath to counteract each other and prevent the piece from warping.

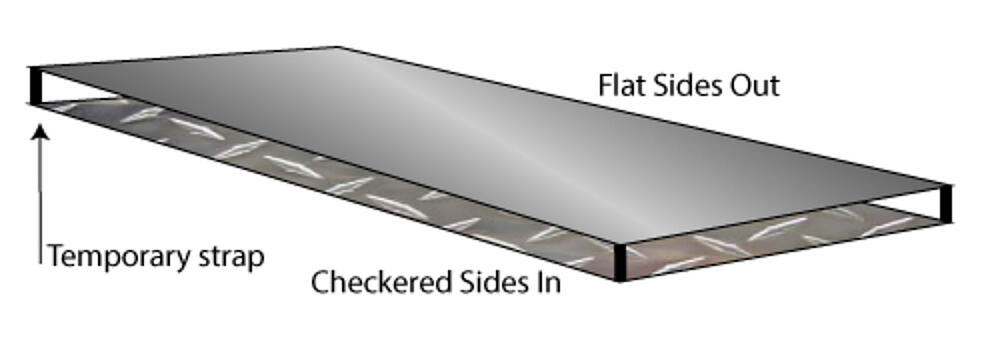

Checker plate is asymmetrical by nature but can be made into a temporary shape that is more symmetrical. If two pieces of the plate are welded face to face with temporary straps, the new symmetrical shape will be much less likely to experience warpage and distortion.

© 2024 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.