Estimating Galvanized Steels Service Life in Soil

How can I estimate the service life of hot-dip galvanized steel in soil?

Corrosion Rates

Due to varying physical and chemical characteristic of soil, it is difficult to predict underground corrosion rates. Even in very close proximity, soil content conditions can have significant variations. In order to predict the performance of hot-dip galvanized steel in the soil, you must first try and classify the soil to which the galvanized steel will be exposed. The properties of soil that have the most effect on the corrosion rate are aeration, moisture content (or time of wetness), pH, temperature, and resistivity.

One of the easiest and most general ways to classify soil is by color. Red, yellow or brown soil indicate a certain extent of oxidized iron, which corresponds to soil that is well aerated. Soils that are gray indicate the presence of reduced iron or soil that is poorly aerated. Poorly aerated soils are generally more corrosive to zinc.

Particle size plays a large role in determining if hot-dip galvanized steel is suitable for use in a particular soil. Particle size will dictate the amount of aeration, as well as the time of wetness for contacting galvanized steel. Soil particle sizes are generally divided into three categories: sand (0.07mm to 2 mm), silt (0.005mm to .07) and clay «0.005 mm). In sandy soils, the larger particle size allows for air to enter between the particles and promote aeration of the soil. At the same time, aerated soils allow moisture that remains in the soil from rainfall or other sources to evaporate at a much faster rate than non-aerated soils of smaller particle size. This resulting aeration and shorter time of wetness correlate to a lower zinc corrosion rate. High levels of bacteria in the soil tend to consume any oxygen present, making the soil poorly aerated. Hot dip galvanized steel will not perform as well in soils containing large amounts of organic bacteria.

Soils also have a wide variety of chemical properties as well as physical properties that make it difficult to predict corrosion rates of zinc. Studies have shown that the pH of soils can vary from 2.6 to 10.2. As with galvanized steel in contact with solutions, the pH has a dramatic effect on the corrosion rate of zinc. Hot-dip galvanized steel performs the best in soils that are neutral or slightly basic. Extreme corrosion rates and deep pitting are associated with soils having very low pH (highly acidic).

Plentiful rainfall typically translates into soils that are more acidic and more corrosive to zinc. Rainfall affects the time of wetness for the soil and increased time of wetness means more corrosive soil.

Temperature also plays a role in the rate at which corrosion of galvanized steel in soil occurs. One study has shown that the corrosion rate doubles in samples when the temperature was raised from 40° to 68° F (4° C to 20° C). The higher temperature results in a lower resistivity of the soil. Some studies have shown corrosion rates are higher in soils with low resistivities.

Generally speaking, sandy, well-aerated soils with a neutral or slightly basic pH are likely to cause only limited corrosion, most likely below 5 microns/year (0.2 mil/year). Determining whether galvanized steel is suitable for applications in soil is challenging. Following the aforementioned guidelines should provide you with a basic understanding of the corrosion of zinc in soils.

Estimating Service Life

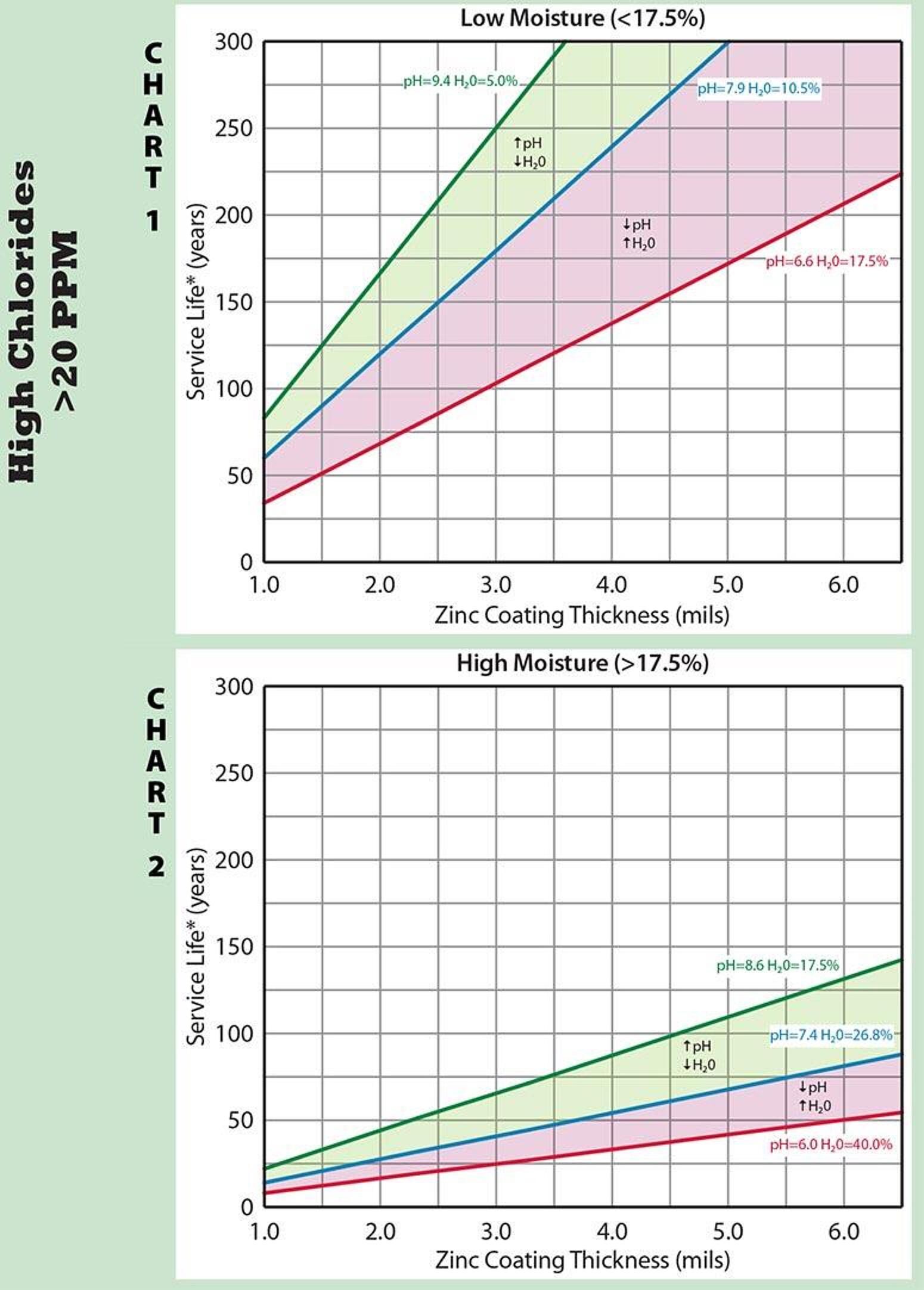

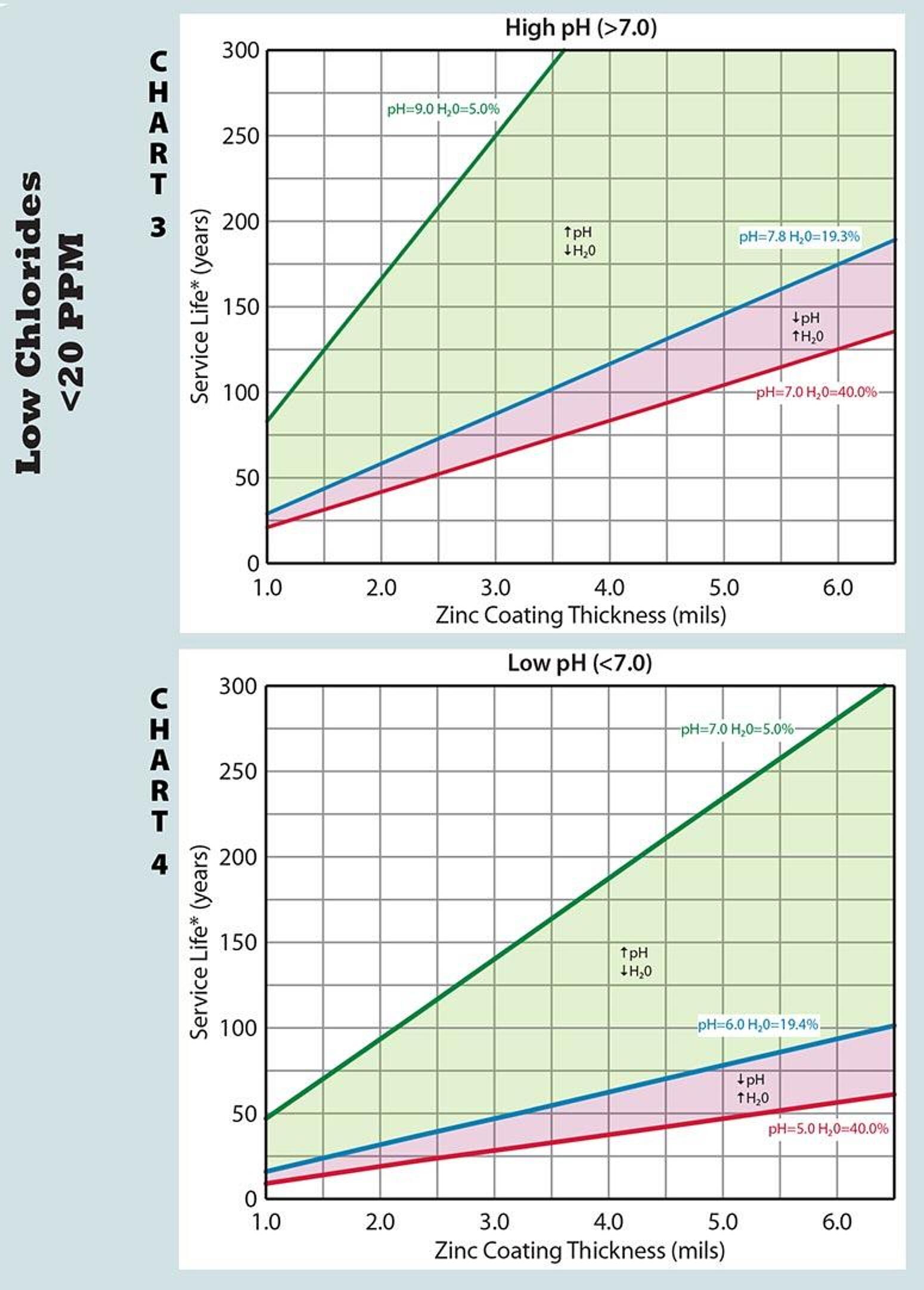

Many studies have observed the corrosion rates various soils have on galvanized steel. Probably the most popular study is a report compiled by Corrpro Companies for the National Corrugated Steel Pipe Association called Condition and Corrosion Survey on Corrugated Steel Storm Sewer and Culvert Pipe. Using the information in this report, the AGA has created four charts that can be used to get a ballpark estimate of the service life of galvanized steel in various soils.

The four charts take into consideration only the soil properties which have the biggest impact on the corrosion rate of galvanized steel rather than attempting to analyze all of the various properties of soil and how they affect the corrosion rate. The soil properties in these charts include chloride content of the soil, moisture content, and pH level. Two charts are for soils with high chloride content (greater than 20 PPM) and include two variables; low moisture and high moisture. For soils with a low chloride content (less than 20 PPM), there are two charts; one for soils with a high pH, and one for soils with a low pH.

- Hot-dip galvanized steel performs well (service life of over 75 years), in most soil conditions.

- The best soil types for hot-dip galvanized steel are sandy, coarse soils with low retained moisture levels.

- The worst soil types for hot-dip galvanized steel are dense soils with high retained moisture levels and swampy soils with high moisture and low pH values.

- Some Western soils in dry areas have very high chloride levels, as well as some other alkali materials and can be very corrosive to galvanized steel, even with very low retention of moisture

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.