Cope Cuts

I've heard there are concerns with steel containing cope cuts to crack when it is hot-dip galvanized. Are these concerns valid? What can I do to prevent the cracking?

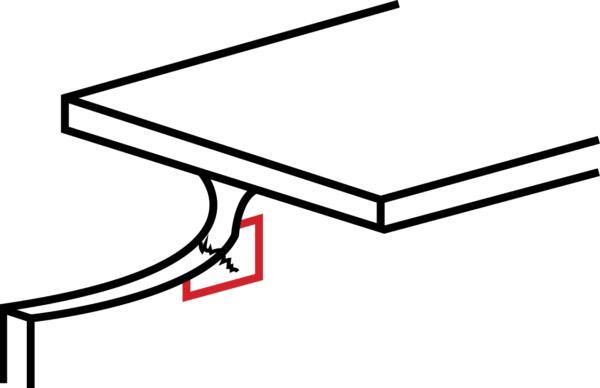

First, it may be prudent to define cope cuts and how they affect the hot-dip galvanizing industry. According to the American Institute of Steel Constructions Steel Construction Manual, a minimum clearance of ½ of an inch should be provided when structural members are framed together. In order to provide this clearance, it may be necessary to remove material from the web and/or flange of structural beams. Flame cutting sections of the material out cope cutting is a practical method for removing this material. Galvanizers may receive steel containing copes that require extra attention before galvanizing.

Hot-dip galvanizers have witnessed instances of cracks around the cope cut areas after the steel has been galvanized. The cuts tend to extend radially from the flame cut radius and are visible on both sides; indicating the cracks extend through the material. The cracks have been known to develop in several types of steel cut with several different methods. Cope cuts can be extremely rough and contain significant residual stress.

What is really tough about this cracking issue is it does not happen all of the time, but only occasionally when the conditions are just right. For cope cracking the frequency of occurrence is about 10%. This makes it very difficult to predict and to prevent. During the mid 90s, ILZRO did a very thorough study of the causes behind cope cracking. The result of that work was there were a number of contributing factors that went into making a certain steel beam susceptible to this type of cracking. There are many different factors needed to exceed a threshold level before the steel would be susceptible to cracking. The most controllable factor was the residual stress in the area of the cope cut. This factor was reduced by applying a weld bead along the edge of the cope on both sides. The main benefit of this process was to reheat the area of the cope and relieve some of the residual stress in the area. This change to the fabricating procedures has lowered the occurrence frequency to less than 1.

Therefore, while cracking only occurs in a limited number of cuts, it is important for fabricators and galvanizers to understand the probability for cracking can be reduced. As described in the ILZRO study, thermal treatment of the cut area may significantly decrease the probability of cracking. A weld bead applied directly to, and extending out one inch from the cut will provide the thermal treatment necessary to reduce the cracking potential, as shown by the highlighted square in the image above. Of course, weld material that is suitable to use before hot-dip galvanizing should be chosen.

But what do you do about the piece that has cracked? Experience with cope cracking has shown the piece can be repaired and put into service. The crack is gouged out to about a ½ in. beyond the tip and the area is backfilled with weld material. This repair is touched-up according to ASTM A780 to provide corrosion protection. The part is then ready to be put into service if approved by the engineer of record. Past experience and inspection of cope cracks repaired using this process show the beams experience no further issues, many in place for over 15 years.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.