Handrail

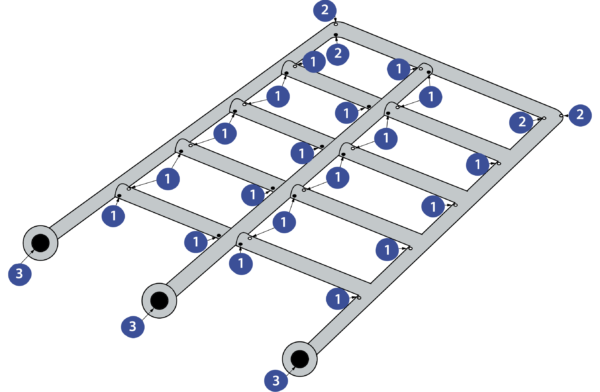

The drawing below illustrates the recommended design for handrail fabrications. The bullet numbers correspond with number references on the illustration.

- External vent holes must be as close to the weld as possible and not less than 3/8" (9.5 mm) in diameter.

- Internal holes should be the full internal diameter (ID) of the pipe for the best galvanizing quality and lowest galvanizing cost.

- Vent holes in end sections or in similar sections must be 1/2" (13 mm) in diameter.

- Ends should be left completely open. Any device used for erection in the field that prevents full openings on ends of horizontal rails and vertical legs should be galvanized separately and attached after galvanizing.

The second illustration (below) shows an acceptable alternative if full internal holes are not used:

- External vent holes must be as close to the weld as possible and must be 25% the size of the ID of the pipe, but not less than 3/8 (10 mm) in diameter.

- Vent holes in end sections or in similar sections must be 1/2 (13 mm) in diameter.

- Ends should be left completely open. Any device used for field-erection that prevents full openings on ends of horizontal rails and vertical legs should be galvanized separately and attached after galvanizing.