Coating Thickness vs. Coating Weight

The usual criterion for determining the expected service life of zinc coatings is thickness: the thicker the coating, the longer the service life. This is an acceptable criterion when comparing zinc coatings produced by the same process.

When comparing zinc coatings produced by different processes, the thickness criterion cannot be used without considering the amount of available zinc per unit volume. It is also important to keep in mind various ASTM or other specifications as they relate to coating weight or thickness, and reduce the coating requirements to a common denominator prior to making a comparison of different zinc coatings.

While the coating densities for some of the different types of zinc coatings are nearly identical, others differ considerably. The coating thicknesses required to equal 1 oz of zinc/ft2 of surface, are displayed in the Coating Densities table below.

| Hot-dip galvanizing (batch or continuous), electrogalvanizing, zinc plating | 1.7 mils (43µm) |

| Zinc Spraying (metallizing) | 1.9 mils (48µm) |

| Mechanical Plating | 2.2 mils (55µm) |

| Zinc-Rich Paint | 3-6mils (75-150µm) |

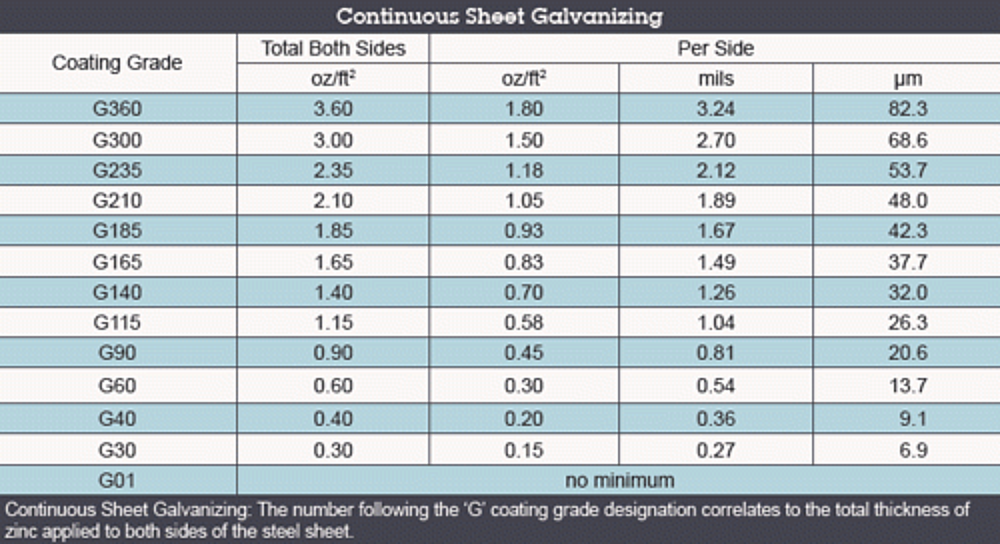

Each of these thicknesses, representing the same weight per unit area of zinc, would be expected to provide equivalent service life; i.e. 1.7 mils of hot-dip galvanized would give about the same service life as 2.2 mils of mechanical plating or 3 to 6 mils (depending on the paint formulation) of zinc-rich paint. It is also important to remember that for all continuous galvanized sheet materials, including electrogalvanized, the coating weight is given for the total zinc weight for both sides of the sheet. To obtain the amount of zinc per unit area of surface, the weight given must be divided in two, assuming equal distribution on both sides. For example, an ASTM A 653 Class G90 sheet contains 0.90 oz zinc/ft2 of zinc or about 0.45 oz/ft2 per side, as seen in the table below.

See Also: Zinc Coatings Publication

© 2024 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.

Comments

Diana

A spec came in for 2 ounces of galv per square foot. How does this translate to mils? Thanks, Diana Couture Seattle Galvanizing

(AGA)

Hi Diana, 2oz/sq-ft is equivalent to 3.3 mils on all sides. There is a conversion chart listed in ASTM A123 Table 2 (the 3rd column) if you need to reference more conversions.

Daniel McCall

Could lighter coating weights of Zinc on metal auto parts contribute to less conductivity in the E-Coating process resulting in parts not painting in the system?

Rda Lizasyon

Is it possible to comment on the galvanising thickness with the knowledge of % weight of galvanising in total weight of structure? For example 4kg zinc weight in 130kg structure. What should be the thickness?

(AGA)

Hi Rda, we have the following information on how much weight galvanizing adds to various types of pieces: https://galvanizeit.org/design-and-fabrication/design-considerations/weight-increase However, the chemistry of the steel will have a large impact on coating thickness, and it is never the exact same for any two pieces.

John Burkhart

What is the life span differance between G-60 galv and G-90 ?

(AGA)

Hi John, G90 has approximately 50% more coating thickness than the G60 coating thickness. Since coating life is directly related to coating thickness, this means a coating designation of G90 would last 50% longer than G60.

CWI

Hi, looking assistance, how much zinc is required to coat a hard drawn wire of 2.45 mm diameter to make it 2.50 mm diameter galvanized wire

Mr. Huang/Kelvion Thermal Solutions

Rekarding to the thickness inspection: How to understand the provisions of zinc layer thickness in ASTM A123:"Each specimen must have minimum average coating thickness of (Table 1)-1 Grade". What is the "-1" grade for Grade 100 of 16mm structural shapes? What is the "-1" grade for Grade 45 of less than 1.6mm plate? Thanks.