Economic Advantages

The specifying community has held the perception for years that hot-dip galvanized steel is cost prohibitive on an initial basis. However, due to regular HDG process improvements and the relatively steady cost of zinc in comparison to soaring price increases for many other coatings, today, hot-dip galvanizing is not only cost competitive, but often less expensive than other corrosion protection systems initially. In addition to overall material costs, hot-dip galvanizing also provides time savings in construction (factory-controlled, independent of weather/humidity requirements, quick turnaround, no curing, etc.) that can provide wider-ranging cost savings during construction.

However, just as in the discussion about environmental impact, the true “cost” of a project is in the life-cycle cost (LCC). LCC takes into account not only the initial material costs, but also the direct maintenance costs throughout the life of the structure as well as the time value of money (inflation and interest) during that life span.

Because hot-dip galvanized steel provides decades of maintenance-free corrosion protection (70+ years), often the initial cost IS the final, life-cycle cost.

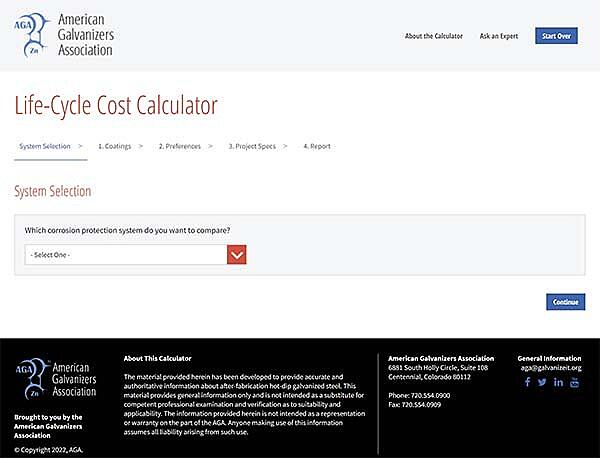

If you’ve ever tried to conduct an LCC analysis, you know it can be quite cumbersome. There is an approved formula for doing so in the specification ASTM A1068 Practice for Life-Cycle Cost Analysis of Corrosion Protection Systems on Iron and Steel Products. To simplify this process, the AGA has created an online Life-Cycle Cost Calculator (lccc.galvnizeit.org) which follows the details of this specification for material costs as well as the calculation of net present value (NPV) and net future value (NFV).

Within the LCCC, users can compare the initial and life-cycle costs of hot-dip galvanized steel (or duplex systems) to more than 30 other corrosion protection coatings. The cost data behind the calculator comes form the following sources:

- Paint – KTA Tator, Inc. - Expected Service Life and Cost Considerations for Maintenance and New Construction Protective Coating Work (2021)

- Hot-Dip Galvanizing – American Galvanizers Association - National Survey (2021)

For more information, visit the online calculator (lccc.galvanizeit.org) or read the AGA’s publication Hot-Dip Galvanizing Costs Less, Lasts Longer.

Cost Case Study

Using the galvanizing cost data obtained through a 2021 survey of North American hot-dip galvanizers and paint cost data taken from a paper produced in 2021 by KTA-Tator (consulting firm specializing in protective coatings, specifically paint) the AGA developed an online tool called The Life-Cycle Cost Calculator (lccc.galvanizeit.org). This is an example using the online calculator, which follows the calculation in ASTM A1068, to conduct a quantitative analysis comparing hot-dip galvanizing to four paint systems, with defined maintenance schedules, in one of the ASTM classified environments.

For this case study, we are analyzing:

- Typical mix of steel shapes/sizes

- 50,000 square foot project

- 70-year design life

- Moderately Industrial (C3) Environment

- Surface Preparation (all coats applied in the shop)

- SP-10 automated (duplex to SP-16)

So, this example could easily represent a short-span bridge, light rail station, stadium, petro-chem plant, etc. In this example, we will evaluate hot-dip galvanizing in comparison to various painted systems, a metallized solution, and duplex system.

Initial Cost

Initial costs take into account the material (paint, metallizing, etc.), as well as the number of coats. Additionally, it examines the cleaning method, where the application will be done, and labor accordingly. For hot-dip galvanizing, the quoted price is inclusive of all of these items, as they are going to be done within the galvanizing plant.

As mentioned before, it is not recommended to analyze only the initial cost for a corrosion protection system. However, if it is the only analysis, galvanizing is still a solid choice, as it is often initially less expensive or very cost competitive with other coating systems. Keep in mind these costs are all coming from the manufacturer (paint manufacturer and/or galvanizer) and do not take into account fabricator markup which may be assigned at varying rates dependent on the material (i.e. galvanizing may be marked up more if the fabricator has his own paint facility).

This example uses a typical mix of structural pieces, which will typically yield an initial galvanizing cost lower than most paint systems, as the galvanizing process efficiently accommodates bundles and groups of steel. However, even if you compare medium or large structural elements, the galvanizing cost is less expensive or within a few cents per square foot of each of these systems as well. The strongly held notion galvanizing is more expensive initially is no longer accurate, as the cost of HDG has remained relatively stable while the cost of paints and other systems have increased significantly over the last 5-10 years.

Life-Cycle Cost

This is where the cost calculation starts to get more complex. In order to calculate life-cycle cost, you must first know the expected life to first maintenance, as well as all future maintenance cycles during the life of the project. This information is reported in the NACE paper for all paint systems (based on the manufacturer’s recommendations provided to KTA Tator). The calculation uses a “practical” maintenance cycle, rather an “ideal,” which means it uses the longest spans between cycles.

Then, because the cost of future maintenance (materials, etc.) will not be the same as they are today, you must also calculate net present value and net future value to account for inflation and interest. These calculations can be found in the specification ASTM 1068.

When life-cycle costs are considered, hot-dip galvanizing is the most economical system for corrosion protection. In fact, this analysis does not even include the hidden (or indirect) costs associated with touch-up, maintenance, and full repainting required for paint systems. If deviations from the practical maintenance schedule occur, life-cycle costs could be significantly higher than indicated.

After 70-years of life, the life-cycle cost of the galvanizing equals the initial cost as no maintenance is required in this environment. Also, when comparing the costs of galvanizing to other systems, the cost savings is significant. The second best option over the life of the project in this example is actually the duplex system of paint over galvanizing because as mentioned before, the galvanized primer allows less maintenance cycles to the painted system than the same system (with IOZ primer) on bare steel.

Also, of note, often the least expensive systems initially (Epoxy/Polyurethane, Epoxy/Epoxy) are the most expensive in life-cycle cost (because they require more maintenance). Even though the metallizing system requires less maintenance, the cost to metallize (and touch up with metallizing in the field) is much higher than it is to use paint in the field.