Coat the Surface

After the hot-dip galvanized surface is thoroughly cleaned, and an anchor has been established for the paint or powder coating, it is important to coat the surface as soon as possible.

Paint

After the surface of the galvanized part has been cleaned and roughened to provide a profile, the part is ready for the final step, painting. Paint can be applied by brushing or spraying onto the galvanized surface. Please follow the paint manufacturers recommendations regarding air conditions and application methods. Painting should begin as soon as possible after cleaning and profiling. There are some paint systems not compatible with zinc coatings; consult the paint manufacturer for information on paint compatibility with zinc coatings and/or refer to SSPC Guide 19.

Powder Coat

Bake

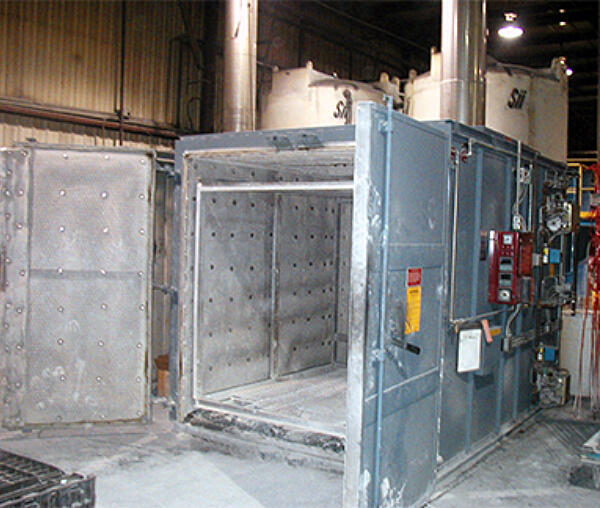

After the galvanized surface has been cleaned and profiled, the part is ready for the next step, baking. This step is extremely important to prevent pinholes and blisters in the powder coating, commonly known as outgassing. Water and air molecules can be trapped in the zinc coating and must be removed through the baking process. The part should be thermally treated in an oven to remove residual moisture prior to powder application to reduce pin-holing and blistering. The temperature of the baking oven should be 30 degrees centigrade above the temperature used to cure the powder. The part should be baked until the part reaches the oven temperature or a minimum of one hour. The part should then be cooled to a temperature that allows the powder application.

Powder Coat

Powder coating should follow baking as soon as possible so there is little or no time for zinc oxidation to begin. Consult the powder manufacturer for information on powder compatibility with zinc coatings. Apply the powder to the galvanized part in accordance with the manufacturers instructions. Powder is typically sprayed onto the galvanized surface. A good practice is to powder coat a sample piece of galvanized steel to check the overall coating appearance before coating the final piece.

Cure the Powder Coating

After the powder application the part should be placed in the curing oven. The oven temperature should be set at the value recommended by the powder manufacturer. The curing time should follow the manufacturers instructions. Since the powder material contains no curing agent, it is critical to the powder coating process to provide an environment where the powder can bond to the galvanized coating.

| Paint of HDG | Powder Coat Over HDG |

|---|---|

| Brush or spray applied | Bake to outgas residual moisture Prevents pinholes and blisters |

| Paint as soon as possible after cleaning and profiling | Apply powder coat as soon as possible after baking Consult with the manufacturer about compatibility with HDG |

| Refer to SSPC Guide 19 for compatible paint systems | Cure the powder coating Follow manufacturers instructions for temperature and time |