HDG & LCA

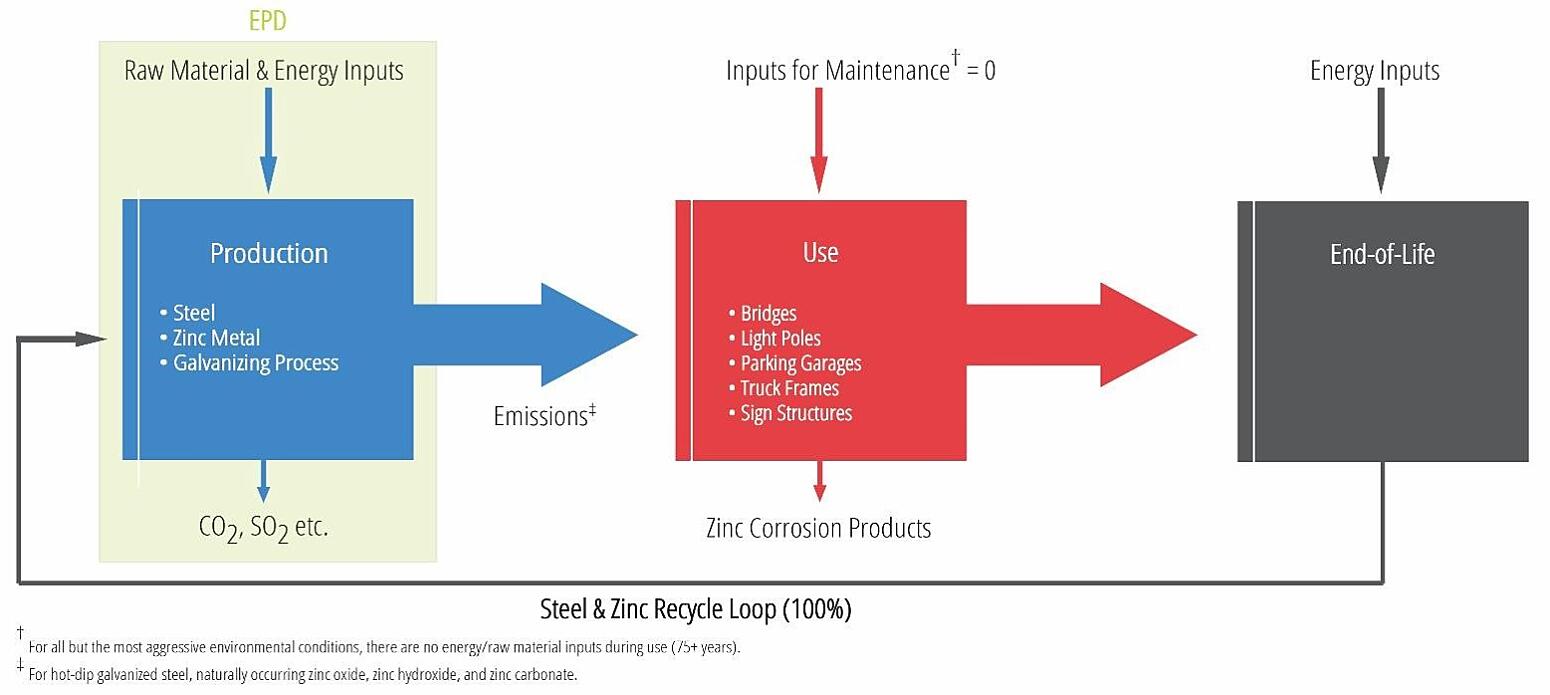

The cradle-to-gate study represented in the EPD is only part of hot-dip galvanized steels sustainability story. When evaluating hot-dip galvanizing on a full life-cycle (cradle-to-grave) basis, there are additional environmental benefits. The longevity of hot-dip galvanized steel means the raw material and energy inputs, as well as the emissions and waste outputs are isolated to the production phase, as there is no maintenance required for 70 years or more in most environments, and HDG is 100% recyclable at the end-of-life.

In 2008, the AGA developed a full life-cycle assessment (LCA) with thinkstep, Inc. (formerly PE International) which shows the environmental impact of hot-dip galvanized steel from the production phase to the end-of-life. The cradle-to-grave study is actually more of a cradle-to-cradle study, as both the zinc and steel of hot-dip galvanizing are 100% recyclable, essentially eliminating a grave for the product. The LCA took into account life-cycle inventories for structural steel, zinc, and the galvanizing process to fully understand the environmental impact of producing hot-dip galvanized steel, then added the use and end-of-life management.

In order to compare the LCA data from 2008 to the EPD study from 2015, the data from both studies were input into the EPAs TRACI 2.0 standards. Looking at the average of the three products from 2015 in comparison to the 2008 average, the impacts are very similar; therefore, it is logical to assume that if the 2015 study was extended to cover use and end-of-life, the impacts would be in line with the 2008 data. Although some impact areas appear to have increased since 2008, it is important to understand there were differences in the data. Most importantly, the 2008 study relied on steel data from the GaBi database and did not fully account for fabrication of the steel, whereas the 2015 study used data from AISC and STI, which did account for total fabrication. Additionally, the 2008 study was an international study and the 2015 study only includes North American data.

| 2008 LCA Data* | |||||

|---|---|---|---|---|---|

| PED (MJ) | GWP (kg) | AP (kg) | EP (kg) | POCP (kg) | |

| Steel | 21,640 | 1.55 | 0.00459 | 0.000536 | 0.000763 |

| Zinc | 2,460 | 0.160 | 0.00115 | 0.0000614 | 0.0000614 |

| HDG Process | 1,800 | 0.0991 | 0.000407 | 0.0000320 | 0.0000265 |

| Total LCA Production | 25,900 | 1.80 | 0.00615 | 0.000568 | 0.000824 |

| *Impact Assessment Method: TRACI 2.0 | |||||

| Comparison of 2008 LCA to 2015 EPD* | |||||

|---|---|---|---|---|---|

| PED (MJ) | GWP (kg) | AP (kg) | EP (kg) | POCP (kg) | |

| Structural (2015) | 19.5 | 1.46 | 0.369 | 0.000201 | 0.0550 |

| Plate (2015) | 23.0 | 1.77 | 0.374 | 0.000237 | 0.0856 |

| HSS (2015) | 32.2 | 2.66 | 0.519 | 0.000362 | 0.1390 |

| EPD (2015) Average | 24.9 | 1.96 | 0.420 | 0.000267 | 0.0932 |

| LCA (2008) Average | 25.9 | 1.81 | 0.328 | 0.000222 | 0.1050 |

| *Impact Assessment Method: TRACI 2.0 | |||||

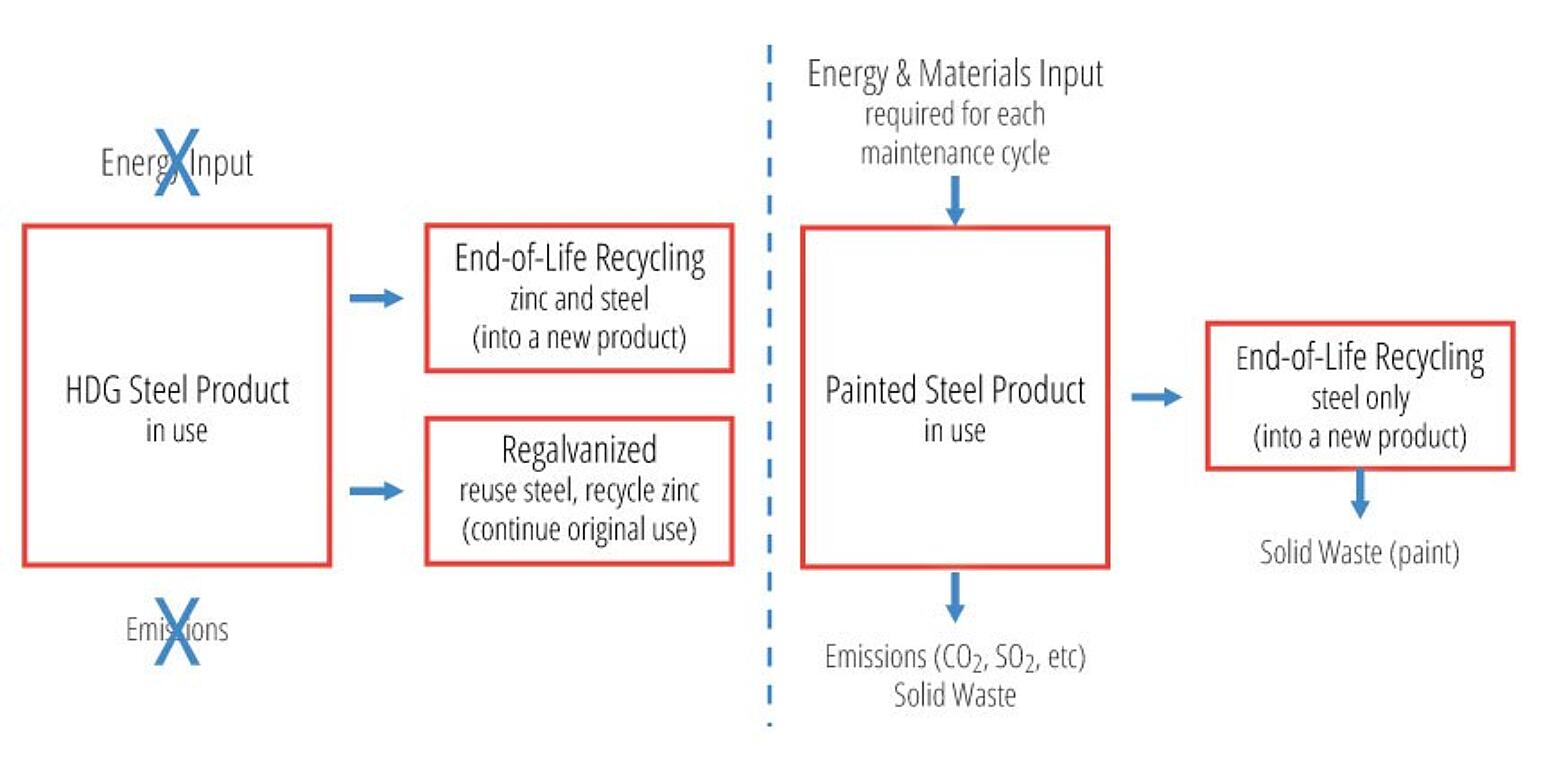

To fully understand the environmental impact of hot-dip galvanized steel, it is important to look beyond the production phase of the product to the use and end-of-life. Hot-dip galvanizing is unique because virtually all of the environmental impact is realized during production. In all but the most aggressive, corrosive environments, hot-dip galvanized steel provides 75 years or more of maintenance-free longevity, meaning during use, there is little or no environmental impact. On the other hand, paint and other corrosion protection systems often require a number of maintenance-cycles which each require energy and material inputs and create emission and waste outputs.

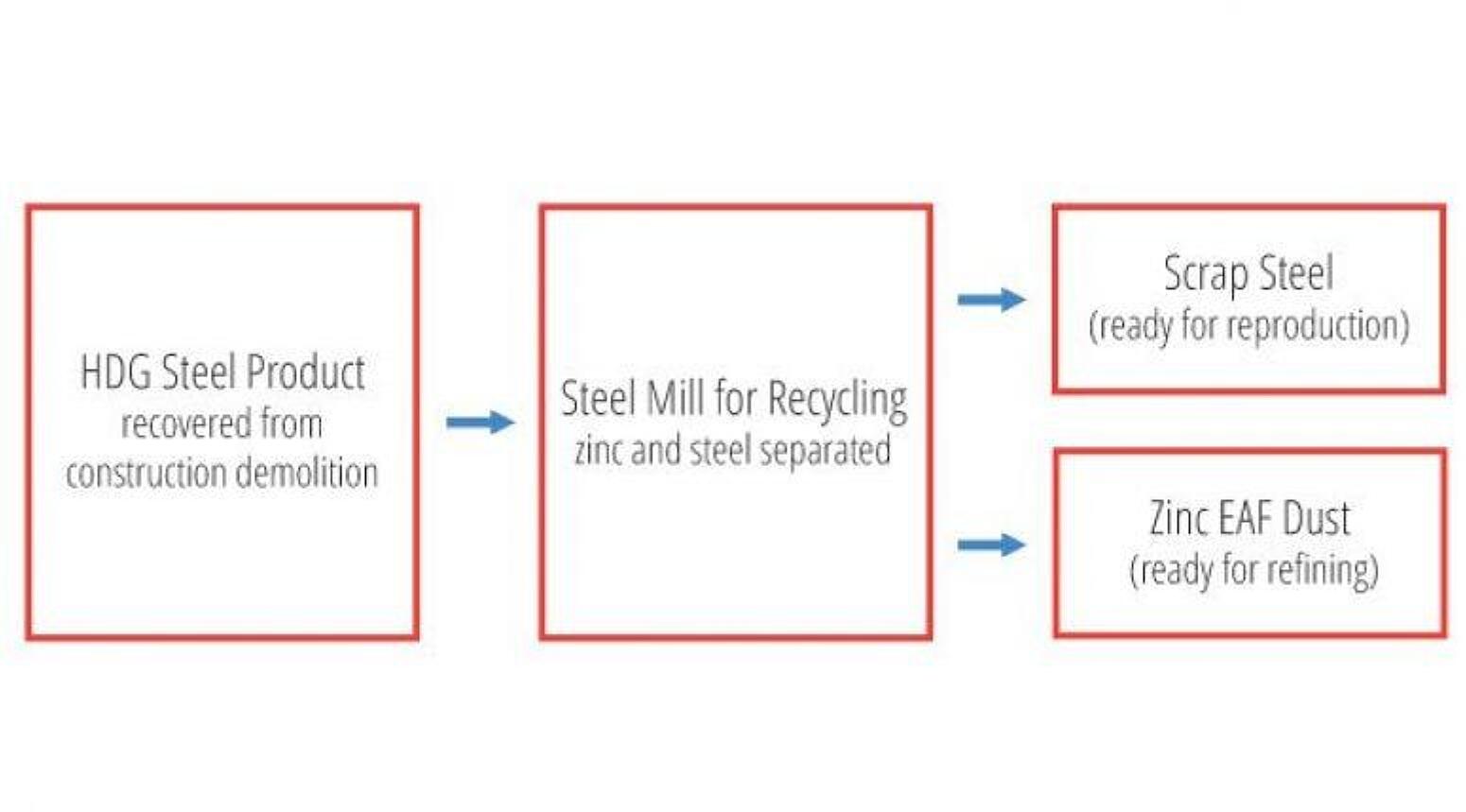

Furthermore, at the end-of-life, both the zinc and the steel of a hot-dip galvanized article are 100% recyclable and able to go back into the production phase to create more zinc and steel. For other coating systems, the coating would be blasted off creating waste, or burned off creating emissions, while only the steel would be salvaged. The recyclability of both the zinc and the steel result in a primary energy demand (PED) credit when considering the full cradle-to-grave (cradle-to-cradle) study.

So, overall the EPD data is very similar to the LCA data, so the data from the full cradle-to-cradle study is still relevant. This is important, because as mentioned before, only looking at the EPD or the environmental impact of producing a product/material does not give you the full story. To truly understand the sustainability of a material, you should look at the impact from raw material acquisition through end-of-life management.