LCA Case Study

The Institute for Environmental Protection Technology at the Technical University of Berlin conducted life-cycle assessments (LCAs) comparing a hot-dip galvanized parking structure to a painted one.

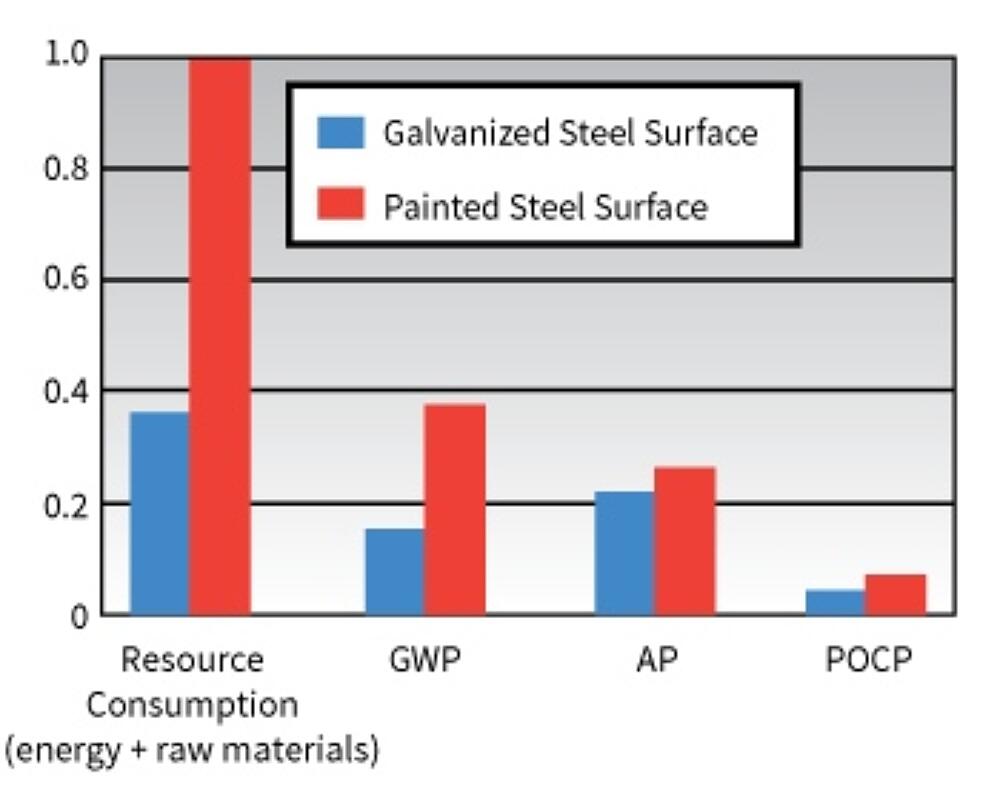

The results of the study demonstrate once again the significant impact the coating plays in the overall environmental impact of the parking garage. The two maintenance cycles required for the painted garage significantly increase the resource and energy consumption of the painted garage. As galvanizing requires no maintenance during the 60-year life, the total energy and resource consumption for the galvanized structure is only 32% of that required for the painted garage.

Environmental Study (LCA) Parameters

Similar to the VTT Technical Research study, the Technical University of Berlin strived to determine the environmental impact of hot-dip galvanizing as well as establish a benchmark for future improvements.

The following parameters were used in the parking structure study:

- 60-year service life

- 1 m2 steel part (20 m2 /metric ton)

- Galvanized coating corrosion rate of 1 micron per year (ISO 1461, C3 environment)

- Paint system: 3-coat system, 240 microns thick

- Paint Maintenance: year 20 and 40 (ISO 12944)

This study also examines the PED, GWP, AP, and POCP values for each system. The results for each impact area are much less for the hot-dip galvanized garage than for the painted one. Similar to the painted balcony, the two maintenance cycles required for the painted garage significantly increase the resource and energy consumption of the painted garage. As galvanizing requires no maintenance during the 60-year life, the total energy and resource consumption for the galvanized structure is only 32% of that required for the painted garage, and the GWP is 38% of paint. Furthermore, the AP is 15% less than paint, and the POCP 33% less (Figure 7).