What welding material yields normal zinc coatings?

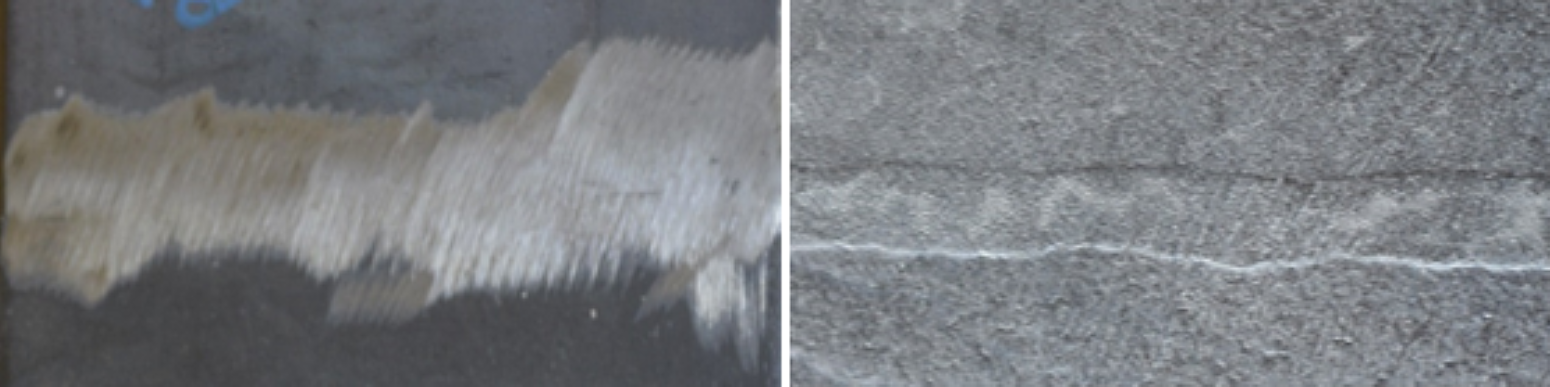

When the selected welding rod material is more reactive than the surrounding steel, a different appearance over the weld can be expected which is often duller in appearance, rougher, and thicker. Where unsure of base metal chemistry, the welding materials listed in Table 1 below can be used to generally reduce coating thickness over the welds, resulting in a more uniform appearance overall.

TABLE 1: RECOMMENDED WELDING MATERIALS FOR MINIMAL THICKNESS OVER WELDED AREAS (UPDATED 2017)

| Welding Process | Lincoln Electric Welding Electrode | AWS Designation | Silicon (Weight %) |

|---|---|---|---|

| SMAW | Jetweld 2 Fleetwood 35 LS | E6027 E6011 | 0.22-0.26% 0.10-0.18% |

| SAW | L60-860 | F6A2-EL12 | 0.24% |

| FCAW | *NR-203 NiC+ NR 203 MP NR 233 NR 311 | E71T8-K2 E71T-8J E71T-8 E70T-7 | 0.06% 0.22-0.26% 0.19-0.20% 0.12-013% |

*Note: It is recommend to use a test plate before use.

See Also:

- The AGA's various publications on Welding

- The Welding category in the Dr. Galv section

- Welding Before HDG

© 2024 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.