Cleanup of Clogged Threads

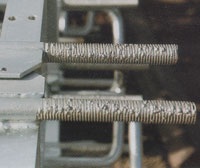

Clogged threads are caused by poor drainage of a threaded section after the product is withdrawn from the galvanizing kettle. Clogged threads, as seen to the left, can be cleaned by using post-galvanizing cleaning operations such as a centrifuge or by heating them with a torch to approximately 500 F (260 C) and then brushing them off with a wire brush to remove the excess zinc. The clogged threads must be cleaned before the part will meet the specification.

© 2024 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.