Environmental Product Declaration (EPD)

An Environmental Product Declaration (EPD), based on a life-cycle assessment (LCA), is a standardized way of quantifying the environmental impact of a product. EPDs are developed following specific Product Category Rules (PCRs) and must be verified by a third-party to meet ISO 14025, 14040, 14044 standards.

The American Galvanizers Association (AGA) has developed an industry-wide EPD for hot-dip galvanized steel after fabrication hot-rolled sections, plate, and hollow structural sections. The EPDs were created by Sphera Solutions, Inc. and verified by UL Environment utilizing data from the AGA, International Zinc Association (IZA), American Institute of Steel Construction (AISC) and Steel Tube Institute (STI). This industry-average EPD can only be used by active members of the AGA in accordance with the ISO standards. Search the AGA's active galvanizer listing.

The EPD for hot-dip galvanized steel is a cradle-to-gate analysis following the product category rule (PCR) for Designated Steel Construction Products, and conform to the requirements in ISO 14040/14044 standards. In essence, the EPDs cover the production of hot-dip galvanized steel from raw material acquisition through the galvanizing process, including steel production and fabrication and zinc refining. It does not account for Construction, Use, or End-of-Life stages, which can be seen in the full life-cycle assessment (LCA) of hot-dip galvanized steel conducted in 2008.

Hot-Dip Galvanizing Impact

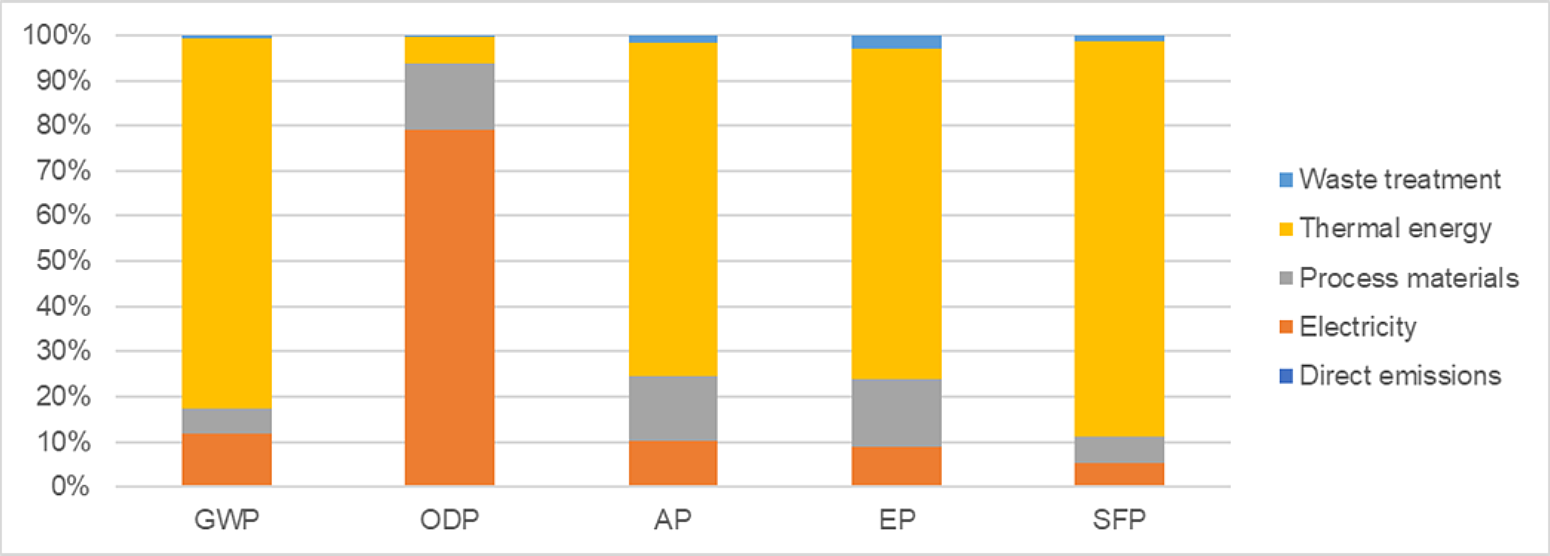

Figure 1 (below) shows the breakdown of impacts of only the hot-dip galvanizing gate-to-gate process. For hot-dip galvanizing, the use of natural gas is the dominant contributor across environmental impact categories considered, except for ozone depletion potential (ODP). Natural gas accounts for around 80% of the global warming potential (GWP) impacts attributed to hot-dip galvanizing. ODP is driven by electricity use. Direct emissions do not contribute to any of the impact categories considered.

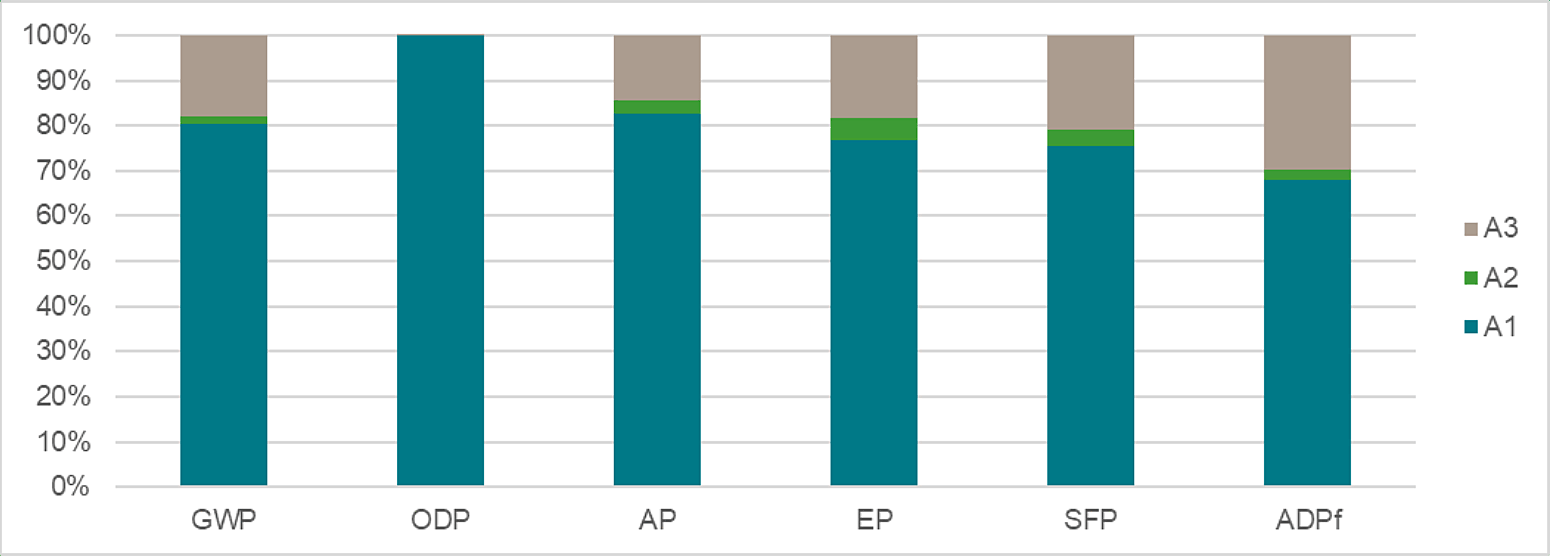

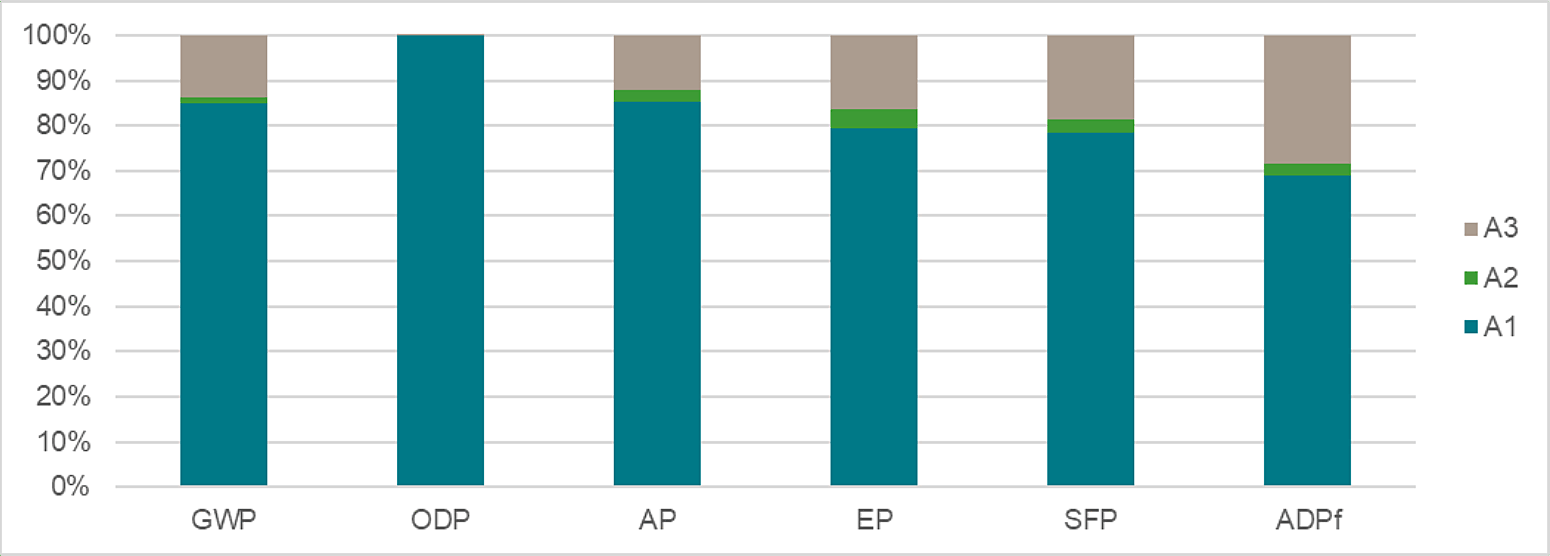

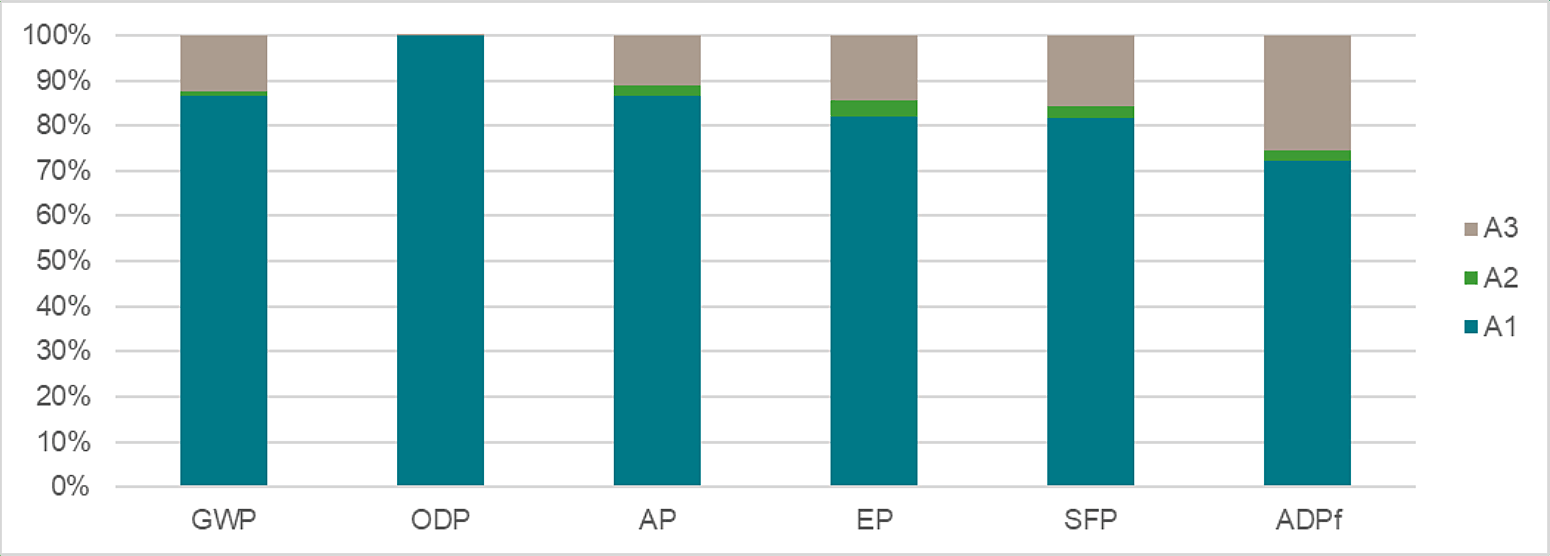

Taking into account the entire life-cycle assessment of a hot-dip galvanized structural steel product, the primary contributor to potential environmental impacts across all indicators is the upstream manufacturing and fabrication of structural steel products and zinc production (A1). In comparison, inbound transportation of the fabricated steel to the galvanizer (A2) and hot-dip galvanizing (A3) also contribute to potential environmental impacts, but to a smaller degree. This is shown in Figure 2, Figure 3, and Figure 4 (below).