Possible Inaccuracies of the Mill Test Report

The test report states the silicon levels are low enough. Why is this piece acting like a reactive steel?

In short, mill test reports are not always accurate. You may be galvanizing a highly reactive steel without even knowing it.

Without the equipment needed to determine the chemical composition and physical properties of steel, fabricators, and galvanizers are at the mercy of the mill test report to establish if the steel is reactive in the galvanizing process. By now, you have likely at least heard the terms Sandelin Curve and the Silicon Equivalent and are aware of the important roles these play in the galvanizing process. Galvanizers and fabricators frequently discuss the silicon content of steel and the quality of the resulting galvanized coating. All the knowledge and experience the AGA shares on this subject makes galvanizers very aware of the issue. The thickness of the coating is very sensitive to the silicon content; and therefore, it is desirable to know the chemical composition of the steel to be galvanized to some degree of accuracy. Unfortunately, the methods used to produce mill test reports contain some systematic errors that decrease the accuracy of the information reported. This means the silicon content reported is not always 100% accurate, and you may be unaware you are working with reactive steel.

A mill test report is produced by taking one unit from a large population of steel and analyzing it for chemical composition and physical properties. This could lead to broad inaccuracies of the reported levels in steel chemistry. In other industries, the tolerance of these values may be relatively large, so there is no problem when the reported silicon level does not give an accurate prediction of the actual level in your piece of steel. However, in the hot-dip galvanizing industry, coating thicknesses are very sensitive to silicon levels and an accurate number is very important.

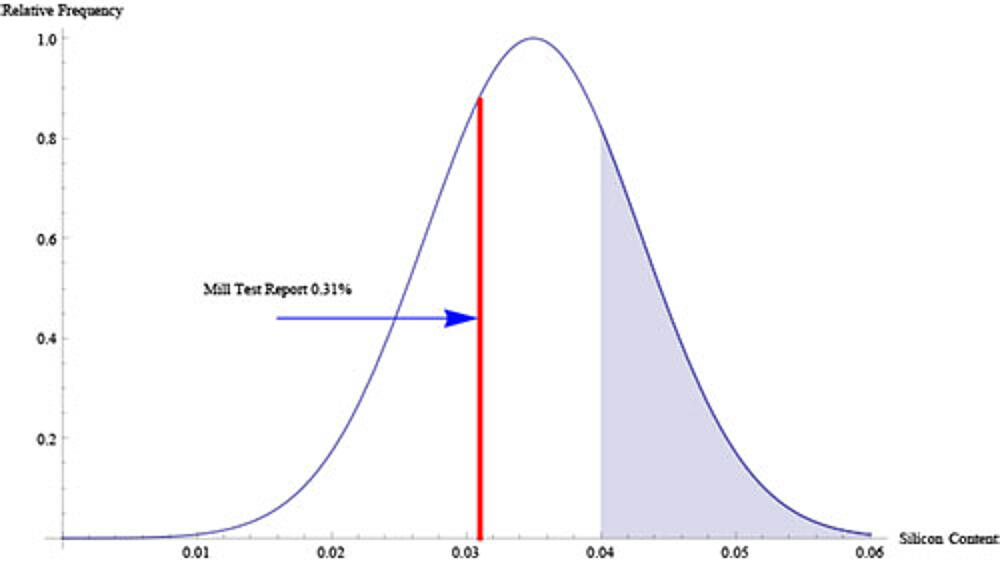

Lets go through an example of what may happen with a mill test report and how it can misrepresent the silicon level you happen to have received. First of all, we can assume the silicon content in a population of steel can be represented by Gauss law of Normal Distribution. This means there will be an average silicon level and, if more samples were taken, we could predict what other silicon levels will be with a known level of confidence. However, only one unit is sampled and further information on the silicon distribution is not recorded. Lets say, for example, the average silicon level within a heat of steel is 0.035% with a standard deviation of 0.008%. The Gaussian curve shown below illustrates this distribution with the shaded portion denoting the reactive range of above 0.04%. Again this information would not be known by you and is only used here as an example.

Now lets say the steel mill selects one random unit for analysis and produces a mill test report. You are presented with this mill test report, or certification, that is supposed to represent the entire population, reporting a silicon content of 0.031% (Shown by the vertical red line on the chart). This is a level that falls below the reactive range of the Sandelin curve and should prove to have little complications during the galvanizing process. But we now know, the one unit sampled does not necessarily 100% represent your steel. You can see from the chart, the silicon level reported has a very good chance of being inaccurate and misleading. Within the population represented by the chart, the silicon value has a very good chance of falling into the 0.04% or above range. There is no way of telling if the steel you have is accurately represented by the unit used by the mill to produce their report. If a larger sample size was taken, and an average was reported, the population would be better represented with a lower error.

This is just one of many reasons your steel certification may lead you to an inaccurate conclusion. One unit sampled from a large population is just not enough to give a full representation of the silicon level present in your steel. Always be aware the number reported could be very different than the level in the steel part you are requested to galvanize.

© 2024 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.