Surface Condition

Successfully painting or powder coating over hot-dip galvanized steel is relatively simple. Just like coating any other surface, proper surface preparation is key to creating an effective bond between the paint or powder and the galvanized surface. It is important for the galvanizer to KNOW you intend to use a duplex system; so he can avoid post-treatments that can hinder the bond of the top coating to the galvanized surface.

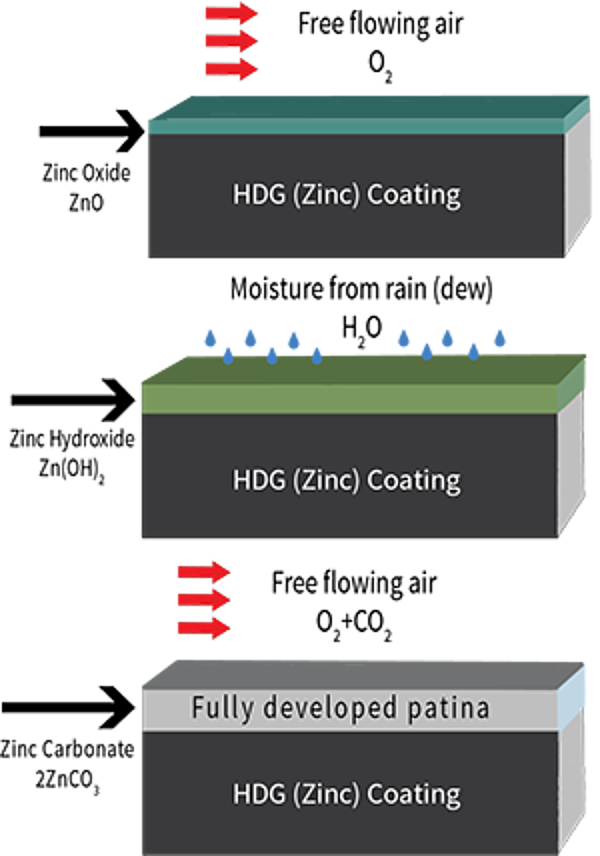

Galvanized steel requires slightly different preparation steps according to the surface condition. As the hot-dip galvanizing surface weathers, different compounds are on the surface which require different cleaning/profiling steps. Properly identifying the surface condition is important as the cleaning and profiling steps required are different based on the stage of the patina development (right). Hot-dip galvanized steel can be and is painted during any of the three phases of development/surface conditions, while powder coating is only done to newly galvanized or partially weathered steel.

Newly Galvanized Steel

Newly galvanized steel has typically been exposed to the atmosphere for no more than 48 hours and has few zinc compounds on the surface. The coating can be bright and shiny, indicating an all-zinc outer layer, or dull gray, indicating a zinc-iron intermetallic outer layer, or a combination of both. Whether bright or dull, the key factor in the newly galvanized condition is a lack of zinc compounds on the surface, which simplifies the cleaning. Some newly galvanized parts, those with a dull gray, can have a rough surface texture, while bright and shiny parts are often smooth. Regardless, if the surface is rough or smooth, profiling the surface by sweep blasting is necessary to ensure the adherence of the paint/powder system.

Partially Weathered

Partially weathered galvanized surfaces have a build-up of zinc compounds and, possibly, organic contaminants such as dirt, dust, oil, or grease. The compounds become attached to the zinc coating by electrostatic forces, and can be expected to release from the surface over time. The zinc compounds, mostly zinc oxide and zinc hydroxide, must be removed before painting. Partially weathered galvanized steel is the most common galvanized surface condition when painting, and also the most difficult to prepare. The partially weathered surface condition is usually present from two days to about one year after galvanizing, depending on temperature variation and humidity factors.

Fully Weathered

Fully weathered galvanized steel has zinc compounds covering the entire surface. The main compound in the fully weathered surface is zinc carbonate. Zinc carbonate is tightly adhered to the surface, is not water soluble, and does not wash off the surface when water hits the part. In this state, the zinc compounds should not be removed, as the paint performs better when the compounds are left on the surface. Fully weathered galvanized coatings are the simplest surface condition to paint. This condition is normally present from one year of exposure to the atmosphere until all the zinc coating has been consumed by protecting the underlying steel, which will take decades. Painting of weathered galvanized steel can significantly extend the service life of the corrosion protection system.