Steel Chemistry & Surface Condition

Most iron-containing (ferrous) materials are suitable for hot-dip galvanizing. Plain carbon steel (under 150 ksi/1100 MPa) and low alloy materials, hot-rolled steel, cold-rolled steel, cast steel, ductile iron, cast iron, castings, fasteners, stainless steel, and even weathering steel can be and are galvanized for enhanced corrosion protection. During galvanizing, the molten zinc reacts with iron in the material being galvanized to form a series of highly abrasion-resistant, corrosion-inhibiting zinc-iron alloy layers, which are normally covered by a layer of almost pure zinc. However, the materials chemical composition influences the characteristics of the galvanized coating.

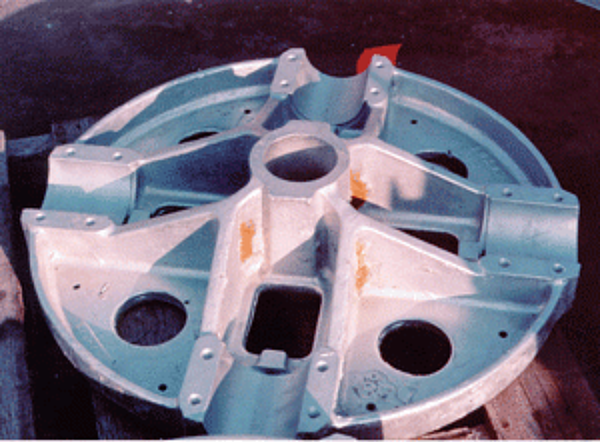

Some parts, such as castings present some unique challenges, but high-quality castings and forged parts are commonly and successfully galvanized. The quality of the galvanizing is strongly influenced by the quality of the casting. As with all steel to be galvanized, cleanliness is very important to achieve completely galvanized cast iron or steel parts. However, conventional cleaning processes employed by galvanizers do not adequately clean castings because sand and other surface inclusions are not removed by chemical cleaning. Thorough abrasive cleaning either by grit-blasting or a combination of grit and shot is the preferred and most effective method to clean the casting and remove foundry sand and impurities. Cleaning is traditionally performed before shipment to the galvanizer. Sound, stress-free castings with good surface finishes will produce high-quality galvanized coatings.

Designing Castings for Galvanizing

- Avoid sharp corners and deep recesses

- Use large pattern numerals and generous radii to facilitate abrasive cleaning

- Specify uniform wall sections. Non-uniform wall thickness in certain casting designs may lead to distortion and/or cracking. Cracking results from stress developed as the temperature of the casting is increased during galvanizing. Uniform wall sections and a balanced design prevents stress buildup.

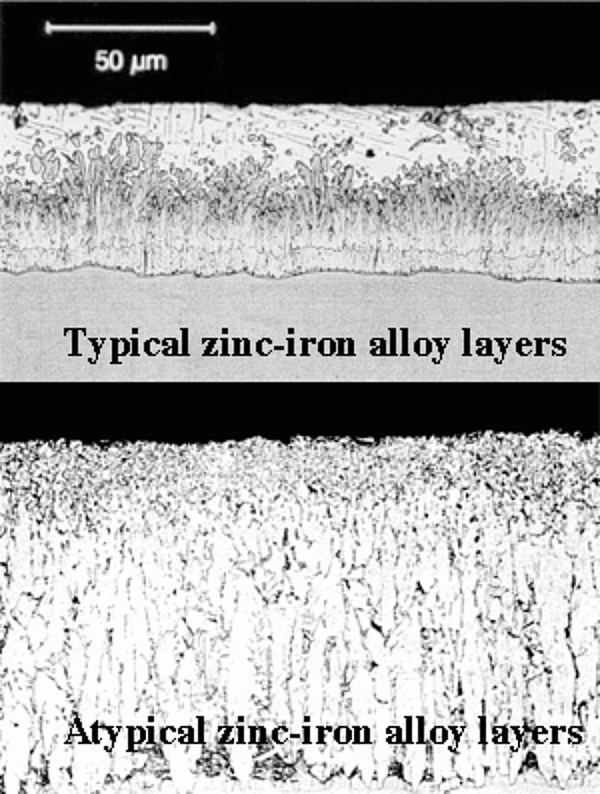

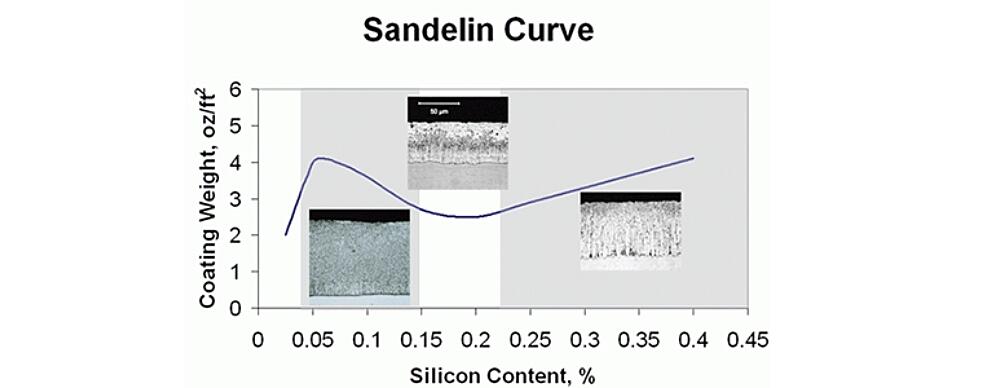

Steel Chemistry

During galvanizing, the iron in the material reacts with the molten zinc to form a series of zinc-iron alloy layers, which are covered by a layer of iron-free zinc. For most hot-rolled steels, the zinc-iron alloy portion of the coating will represent 50-70% of the total coating thickness, with the free zinc outer layer accounting for the balance. Steel compositions vary depending on strength and service requirements. Trace elements in the steel (silicon, phosphorus) affect the galvanizing process as well as the structure and appearance of the galvanized coating. Steels with these elements outside of the recommended ranges are known in the galvanizing industry as highly reactive steel, and may produce a coating composed entirely, or almost entirely, of zinc-iron alloy layers.

Atypical coatings produced from reactive steels exhibit different coating characteristics than a typical galvanized coating such as:

- Appearance: The atypical galvanized coating may have a matte gray appearance and/or rougher surface due to the absence of the free zinc layer. The free zinc layer present on typical coatings imparts a shinier finish to a galvanized coating.

- Adherence: The zinc-iron alloy coating tends to be thicker than a typical galvanized coating. In the rare situation where the coating is excessively thick, there is the possibility of diminished adhesion under external stress (thermal gradients, sharp impact).

Reactive steels are still galvanized on a regular basis, and it is important to note differences in appearance have no effect on the corrosion protection afforded by the galvanized coating. The performance of the coating is based on the thickness of the zinc; therefore, often the duller (and thicker) coatings produced by reactive steels last longer. Furthermore, all galvanized coatings will develop a uniform matte gray appearance as they weather over time.

It is difficult to provide precise guidance in the area of steel selection without qualifying all steel grades commercially available. However, these guidelines discussed will assist you in selecting steels that provide good galvanized coatings.

- Levels of carbon less than 0.25%, phosphorus less than 0.04%, or manganese less than 1.35% are beneficial

- Silicon levels less than 0.04% or between 0.15% - 0.22% are desirable

Silicon may be present in many steels commonly galvanized even though it is not a part of the steel's controlled composition because silicon is used in the steel deoxidation process and is found in continuously cast steel. Both silicon and phosphorous act as catalysts during the galvanizing process, resulting in rapid growth of zinc-iron alloy layers. Even when both elements are individually held to desirable limits, the combined effect between them can still produce an atypical coating of all or mostly zinc-iron alloy layers. When possible, your galvanizer should be advised of the grade of steel selected in order to determine whether specialized galvanizing techniques are suggested.

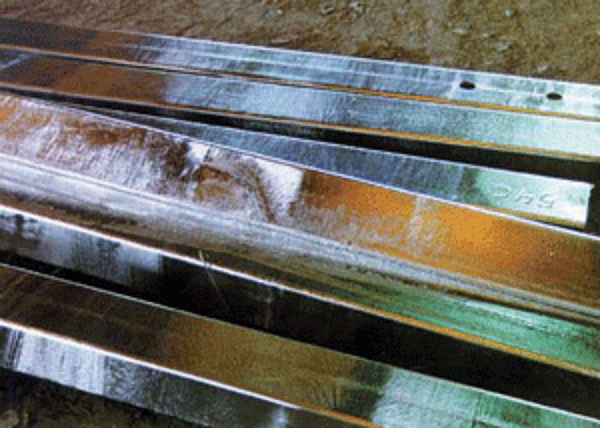

Varying Surface Conditions

Varying surface conditions, different fabrication methods, or ferrous metals with special chemistries, when combined, make it difficult to produce coatings with uniform appearance. This is because different parameters for pickling (immersion time, solution concentrations, temperatures) and galvanizing (bath temperatures, immersion time) are required for:

- Coatings such as paint, lacquer, etc. on the steel

- Excessively rusted surfaces

- Machined surfaces

- Cast steel

- Malleable iron

- Hot-rolled steel

- Cold-rolled steel

- Cast iron, especially with sand inclusions

- Pitted surfaces

- Steel containing excess carbon, phosphorus, manganese, or silicon

Paint & Lacquer

Many coatings such as paint and lacquer cannot be removed from the steel with the chemical cleaning process used in the galvanizing facility. As perfectly cleaned steel is required for the metallurgical reaction to occur in the galvanizing kettle, these contaminants need to be removed mechanically from the surface prior to sending the fabrication to the galvanizer.

New or Old Steel

The use of old along with new steel, or castings with rolled steel in the same assembly, should be avoided. Where assemblies of cast iron, cast steel, malleable iron, or rolled steel are unavoidable, the entire assembly should be thoroughly abrasive blasted prior to pickling to give the best chance for producing a consistent galvanized coating appearance.

Excessive Rust

Similarly, excessively rusted, pitted, or forged steels should also not be used in combination with new or machined surfaces because the difference in required pickling time for sulfuric acid pickling baths can cause over-pickling of the new or machined surfaces. Where this combination is unavoidable, a thorough abrasive blast cleaning of the assembly (normally before any machining is done) provides a more uniform galvanized coating.

Abrasive Blasting Before Galvanizing

If abrasive blast cleaning is used to prepare a surface for galvanizing, a coating thicker than normal will be produced for low silicon steel. Abrasive cleaning roughens the steel surface and increases its surface area, resulting in increased reactivity with the molten zinc.

The best practice when combining different materials and surfaces is to galvanize separately and assemble after galvanizing. This will help facilitate efficient turnaround times in the process, eliminate over-pickling, and allow the pieces to be matched for appearance. Whether run through the galvanizing process joined or separately, the differences in appearance on assemblies containing steels with varying surface condition do not affect the corrosion protection. Furthermore, after aging in the environment, all surfaces will exhibit a uniform matte gray appearance.