Bending Before HDG

Bending before galvanizing is often preferred by designers as the recommended bend radius is tighter than for steel bent after galvanizing. However, fabricators must be aware of the added stress cold working introduces into the steel. ASTM A143 Practice for Safeguarding Against Embrittlement of Hot-Dip Galvanized Structural Steel Products and Procedure for Detecting Embrittlement recommends the minimum bend radius for any part that will be hot-dip galvanized.

Regardless of the corrosion protection system decided upon, it must be factored into the design of the product. Many structures and parts are designed to include bending and other cold-working techniques. It is important for both the fabricator and designer to understand because bending-induced stresses may be released during the galvanizing process, changes in structural shape and/or alignment (warping and distortion) may result.

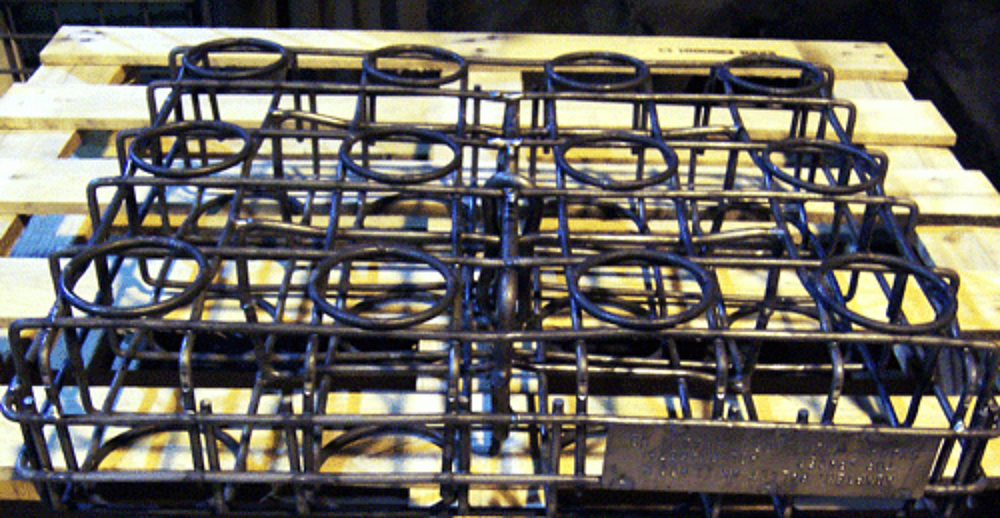

Best practice is to keep bend diameters as large as possible when parts are bent before galvanizing. ASTM A143 recommends a minimum bend radius of three times the section thickness to promote optimum quality galvanized coating properties. This allows for some cold work in the bend area without causing cracking of the steel.

As steel goes through the galvanizing process, the steel cycles from ambient temperature to molten zincs temperature of more than 800 F (420 C) and then back to ambient temperature. During the rise and fall of steel temperature mechanical property changes can occur, including an aging, called strain-age embrittlement of areas on steel parts where there is a significant amount of cold-working, such as bends.

When the cold-worked and galvanized part is later put in service, a fracture of the bend may occur. Fractures characteristically occur at the toe of the bend where the highest induced stress resides.

If bends sharper than three times the section thickness are necessary, thermally heat-treat (stress-relieve) the article after bending prior to galvanizing in order to reduce the retained stress level in the steel article. To stress-relieve, the part should be heat-treated at 1100 F (593 C) for one hour per inch (2.5cm) of section thickness.

Minimum Finished Bend Diameters - Inch - Pound Unit

| Bar No. | Grade 40 | Grade 50 | Grade 60 | Grade 75 |

|---|---|---|---|---|

| 10, 13, 16 [3,4,5] | 6d A | 6d | 6d | -- |

| 19 [6] | 6d | 6d | 6d | 6d |

| 22, 25 [7,8] | 6d | 8d | 8d | 8d |

| 29, 32 [9, 10] | -- | -- | 8d | 8d |

| 36 [11] | -- | -- | 8d | 8d |

| 43, 57 [14, 18] | -- | -- | 10d | 10d |

| A d=nominal diameter of the bar. Table taken from ASTM A767 | ||||