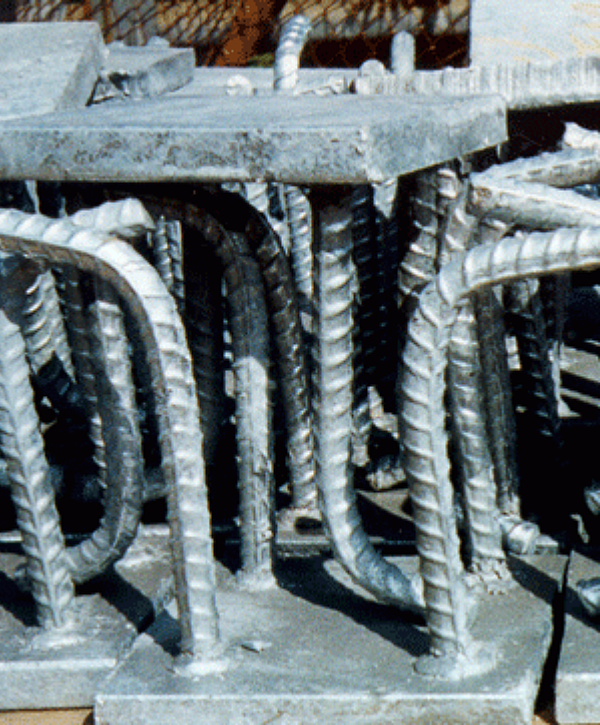

Bending After HDG

Hot-dip galvanized coatings are made up of a series of corrosion-inhibiting, highly abrasion-resistant zinc/iron alloy layers. To maintain this protective coating's integrity, guidelines exist for bending parts after galvanizing:

- Keep bend diameters as large as possible

- Be careful not to bend to an extreme degree in relation to the article's diameter or section thickness.

- If possible, bend immediately after galvanizing, or when the part is hot

- The speed at which the article is bent also may affect coating integrity. The galvanized coating is best maintained at slower bend speeds.

According to ASTM A767, some cracking and flaking of the galvanized coating in the bend area is not cause for rejection. Any flaking or cracking can be repaired as described in ASTM A780.