Part Identification

One important consideration in the design of products to be hot-dip galvanized is the identification of parts throughout the fabrication and galvanizing process. Parts are marked to ensure they are not lost during processing as well as to identify the project, customer, and/or assembly in which they belong.

Part identification is often critical for quick turnaround times and complex configurations, such as the Salvador Dali Museum in St. Petersburg, Florida. One of the benefits of hot-dip galvanizing is coating quality and integrity are readily apparent - zinc will only react and metallurgically bond to clean steel. Therefore, surface preparation is paramount in providing optimum zinc coatings, and uniformity is visible as soon as the steel is withdrawn from the molten zinc.

There are a variety of products used for identifying steel that are not removed during the chemical cleaning phases of the galvanizing process, including paint, grease, and oil-based markers. Though, initially this may sound desirable, it is actually a problem because no galvanized coating will form in these areas if the surface is not clean. Therefore, other forms of identification are recommended including:

- Temporary identification - detachable metal tags (metal barcode tags are also available) or water-soluble paint or markers

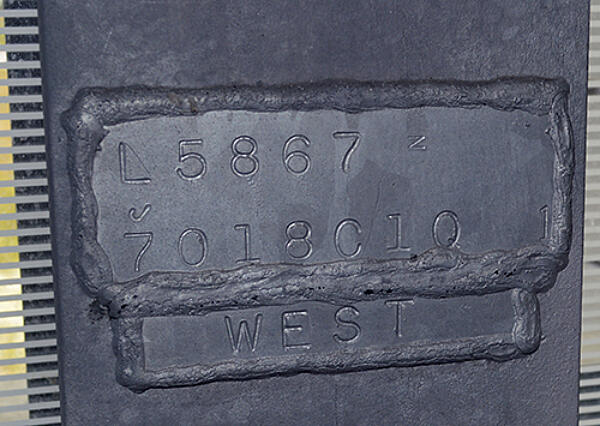

- Permanent identification - stamping, weld beads, and deep stencil marking

For more information on temporary and permanent identification practices, please see Marking Parts under Fabrication Considerations.