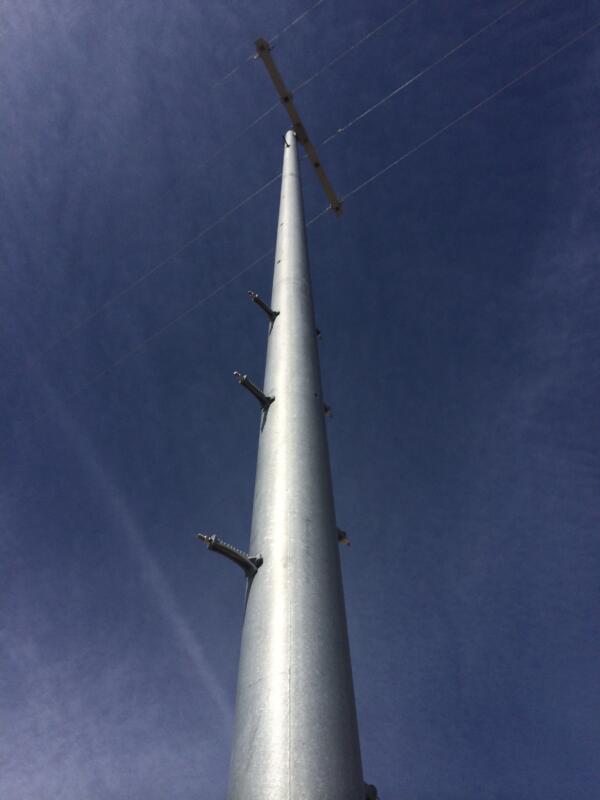

Take a Second Look at Steel: Hot-Dip Galvanized Steel Sustainable Solution for Distribution Poles

Sustainable development is not a new concept, but becomes more wide-spread every day. There is increased demand to develop North Americas infrastructure using environmentally-friendly and economically practical materials. Both the public and private sectors strive to not only sustain, but improve the quality of life for future generations by making responsible, forward-thinking decisions. One important piece of the nations infrastructure is power transmission and distribution lines something we all rely on to power our homes, offices, and communities.

In North America, most transmission and distribution lines are above ground supported by poles and cross arms. The majority of the poles are made of either chemically-treated wood or steel. In 2014, steel poles accounted for approximately 50-55% of the total expenditures by electric utilities for the transmission and distribution pole market; however, the majority of these are in the transmission market while wood is used more in the distribution market. As steel, and in particular hot-dip galvanized steel which is common throughout generation facilities, substations, lattice towers, transmission lines, and renewable energy structures, has provided the backbone of North Americas power infrastructure for decades, its natural to ponder why so little is used in the distribution market.

The typical answer heard from electric utilities is initial cost. The initial cost of a steel distribution pole is usually higher than for wood poles, but its important to look at all future costs such as maintenance and those associated with the replacement as well. The initial cost is a hurdle which many utilities have overcome by looking forward to the long term and overall life cycle of steel poles versus wooden poles. Traditional wood poles have a life-span of approximately 30 years while steel poles often remain in use anywhere from 50-80 years. In a steel distribution pole case study conducted by utility BlueBonnet Electrical Cooperative (Texas), Thomas Ellis, BlueBonnet Manager of Engineering said, the big savings is that we dont have go back in 30 years to replace hard-to-reach poles. On an initial cost basis, steel poles are typically more expensive than wood poles under 50 feet in height, and most distribution poles in North America are 40-45 feet. Transmission poles, where steel is used more heavily, are often larger and steel is more cost competitive at those lengths. However, as the interest in and demand for sustainable development increases, life-cycle costs both environmental and economic are becoming more important.

From an environmental standpoint, many specifiers think of wood as a natural, sustainable material. Though the wood itself is natural, wood poles require chemical treatments to provide longevity. Many of these chemicals have negative environmental impacts emitting harmful toxins into the air, soil, or ground water. In fact, one chemical treatment, pentachlorophenol (PCP), used on approximately 38% of poles in the U.S. was recently added to Annex A of the Stockholm Convention on Persistent Organic Pollutants (POPs). A listing on Annex A means the chemical has been identified to pose serious threats to human health and the environment, and parties to the convention are required to discontinue its use in the next five years. (It should be noted the U.S. is not currently a signatory of the Stockholm Convention.)

Part of the process of labeling a chemical a POP is a risk management evaluation, which includes an examination of viable alternatives. The evaluation for pentachlorophenol (PCP) identified a number of chemical alternatives, as well as non-chemical alternatives including steel poles. Many of the other chemical alternatives to treat wood poles have their own negative environmental impacts. If the U.S. does follow the recommendation of the Convention (which it has shown progress in phasing out other POPs in the past), it may be time to consider hot-dip galvanized steel distribution poles as an alternative.

Hot-dip galvanizing is a zinc corrosion protection system applied to steel to provide maintenance-free longevity. The primary components of hot-dip galvanized steel, zinc and iron ore (steel), are both abundantly found in the Earths crust. In fact, iron ore is the 4th most abundant element, and zinc is the 24th. In addition to being natural and readily available, both steel (the most recycled material in the world) and zinc are infinitely recyclable without the loss of any physical properties. Steel and zinc can be multi-cycled used as steel and zinc again rather than being down-cycled as most other products are. Therefore, hot-dip galvanized steel is an infinitely renewable building material.

In addition to utilizing natural, abundant, recyclable materials, galvanized steel poles do not emit harmful toxins into the environment while in use. As galvanized steel weathers, the zinc surface reacts with air during natural wet and dry cycles to form zinc oxide, zinc hydroxide, and zinc carbonate. These byproducts are already naturally found in water, soil, and the air. In fact, zinc is essential to all life from humans to the smallest microorganisms. Unlike wood poles, and many other building products, hot-dip galvanizings energy inputs and emission outputs (environmental impacts) are isolated in the production phase, because no maintenance (for 75+ years) is required during use in atmospheric exposure. Therefore, any environmental impact from producing hot-dip galvanized poles is averaged over the decades of maintenance-free life before 100% recyclability at the end-of-life. All of these factors provide steel poles a net positive environmental effect over wood poles.

True sustainable development calls for both environmental and economic responsibility to benefit future generations. As mentioned, steel poles can be more expensive initially. However, steel poles, particularly hot-dip galvanized poles, have been shown to save 10-20% over the life-cycle when compared to wood poles. Investing in the future through sustainable development dictates life-cycle costs both economic and environmental should carry more weight than initial costs.

Beyond the environmental and economic savings over the life, hot-dip galvanized distribution poles can provide a number of other advantages such as: strengthening the line, lighter weight which leads to lower shipping and installation costs, less damage during catastrophic events (fire, wind, etc.), and more. There are a number of resources available to learn about the positive impact of hot-dip galvanizing and steel distribution poles including specifying and installing steel poles into existing wood lines through the Steel Market Development Institute (SMDI).

For many years, the primary focus of construction spending in the power market has been in the development of generation sources. However, as transmission and distribution grids continue to age, it is projected North America will spend billions of dollars on power lines in the next five years. With the tenets of sustainability in mind and the addition of one common wood pole treatment (PCP) to Annex A of the Stockholm Convention, now is the time to give hot-dip galvanized steel distribution poles a second look.

More information on PCP and/or steel distribution poles: