San Francisco/Oakland Bay Bridge Update

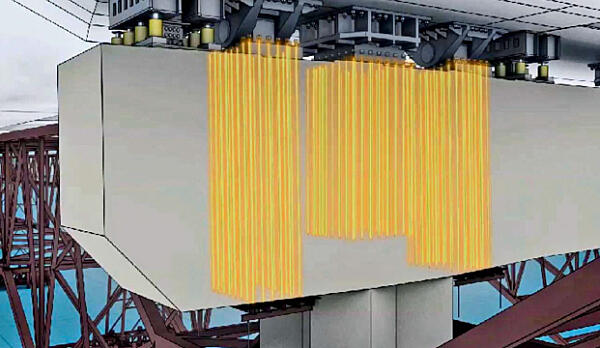

The San Francisco‐Oakland Bay Bridge (SFOBB) is connected to Pier E2 at the east side by means of 96, 3‐inch diameter, galvanized ASTM A354 Grade BD (A354BD) anchor rods fabricated and installed inside the Pier E2 concrete bent cap in 2008 (2008 Rods). In early March 2013, after erection of the superstructure and load transfer was completed, the rods were pre‐tensioned to 70% of their minimum specified ultimate tensile strength (Fu). A few days after tensioning was completed, during the first two weeks of March 2013, 32 of the 96 anchor rods fractured. All 32 fractures occurred at or near the threaded engagements at the bottom ends of the rods. Failure of the rods ceased after the pre‐tension level in the remaining rods was reduced to 0.40 Fu in mid‐March. All of these 96 rods were abandoned and an alternative anchoring system was successfully designed and installed.

Although the 2008 rods are no longer in service, their failure raised concerns about the long-term performance of the remaining A354BD rods on the bridge. An initial metallurgical investigation concluded that the 2008 rods failed as a result of hydrogen embrittlement. The California Department of Transportation undertook a testing program to further examine the cause of failure, and to evaluate the suitability of all other A354BD rods on the bridge.

Groups of rods representing the various sizes, tension levels, and locations on the bridge were selected for detailed laboratory testing to determine chemical composition and hardness. These results showed the material properties were generally uniform and within specification requirements. Although not required by specification, Charpy impact toughness tests were also conducted. These tests showed the toughness of the majority of the remaining rods is within normal ranges for this material. Charpy tests performed on samples of the 2008 rods, however, showed significantly lower toughness values.

The Townsend Test for Stress Corrosion Cracking (SCC) or hydrogen embrittlement susceptibility was performed on full‐diameter rods selected from the various groups of rods. The selected rods were representative of the population of rods on the bridge in terms of hardness range, diameter, and thread forming. In this test, the tensile load is increased very slowly (in steps) until a threshold load level is established for the onset of cracking due to hydrogen embrittlement. The slow rate of loading is essential to detect the effects of hydrogen that require time for diffusion. With applied loads up to 1.86 million pounds, the scale of this test is unprecedented for hydrogen embrittlement testing. To determine the threshold load for hydrogen entering the steel from the environment due to corrosion (environmental hydrogen), the rods were loaded while immersed in salt water containing 3.5% sodium chloride. The main results of these tests are:

- 2008 rods failed by hydrogen embrittlement at the same load (0.70 Fu) that resulted in failure on the bridge, and with similar fracture characteristics. This result provides confirmation that the Townsend Test duplicates the actual performance of these rods.

- All other groups of rods exhibited threshold loads greater than their design loads, indicating the remaining rods are not susceptible to failure by hydrogen embrittlement under the design loads, even under the worst‐case scenario of exposure to salt water as long as the galvanized coating remains intact.

To explore the possibility that hydrogen already present in the steel (internal hydrogen) could have contributed to the low threshold of the 2008 rods, the Townsend Test was repeated in air, without exposure to salt water. These tests showed a complete absence of hydrogen embrittlement. This result clearly demonstrates the following:

- Failures of the 2008 rods in the wet Townsend Tests occurred as a result of environmentally induced hydrogen embrittlement.

- 2008 rods would not have failed if they were protected from water.

The Raymond Test is a slow, rising step‐load laboratory bend test for susceptibility to hydrogen embrittlement. It was conducted with two types of small specimens cut from full‐size rods. In one type, a pre‐crack was introduced into rectangular bars to establish material susceptibility according to fracture mechanics procedures. These results were consistent with previously published tests of pre‐cracked specimens of this material. A second type of specimen included the threaded portion of the as‐built rod without a pre‐crack. Testing these specimens gave results consistent with the results of the Townsend Test, thus providing independent confirmation of the results obtained with full‐diameter rods.

All results of this study indicate the 2008 rods on the bridge failed by environmentally induced hydrogen embrittlement because they were tensioned above their hydrogen embrittlement threshold while simultaneously immersed in water, which served as the source of hydrogen. The low hydrogen embrittlement threshold of the 2008 rods is likely due to rod fabrication methods, not galvanizing processes.

There is no evidence hydrogen was present in the steel prior to installation or tensioning nor that internal hydrogen contributed to the 2008 rod failures. On the contrary, the Townsend Test performed on the 2008 rods in salt solution and in the dry confirmed that without the presence of water, these rods would not have failed. All remaining A354BD rods on the bridge exhibit hydrogen embrittlement thresholds higher than their pre‐tension stress levels and are safe. All A354BD rods on the bridge were designed to have supplemental corrosion‐protection measures, such as dehumidification, paint system, or grout, which would prevent corrosion and further rule out any future possibility of hydrogen embrittlement.

The testing program results show the A354BD rods on the bridge exhibit hydrogen embrittlement thresholds higher than their pre‐tension stress levels and therefore are safe against environmentally induced hydrogen embrittlement as long as the galvanized coating remains intact. Based on the findings of this investigation, nothing further is needed to ensure the integrity of the SAS A354BD rods, other than providing a supplementary barrier to the Pier E2 top housing shear key and bearing rods, and application of customary maintenance procedures, which will be specified in the Bridge Maintenance Manual.